- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Applications of temperature transmitters in the manufacturing industry

2024-06-26 16:50:12

Applications of Temperature Transmitters in the Manufacturing Industry

Understanding Temperature Transmitters

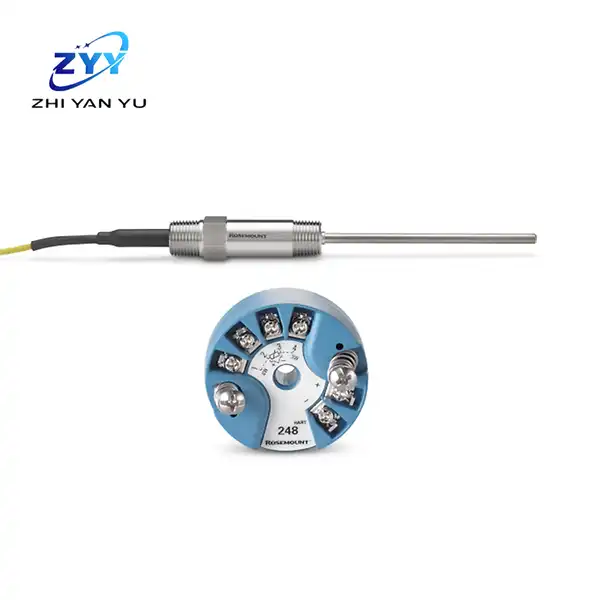

Rosemount 214c Temperature Sensor an essential part in different modern applications, particularly in the assembling area.

These gadgets are intended to quantify temperature precisely and dependably in unforgiving conditions, making them imperative apparatuses for process control and observing. In this part, we will dig into the essentials of temperature transmitters, investigating their usefulness, types, and key elements.

Temperature transmitters are electronic gadgets used to change over temperature signals from sensors into normalized yield signals, like 4-20 Mama or computerized signals. They are basically utilized in modern cycles where exact temperature estimation and control are fundamental for guaranteeing item quality, wellbeing, and proficiency. Not at all like conventional temperature pointers, transmitters offer a few benefits, including remote observing capacities, signal molding, and similarity with control frameworks.

There are different kinds of temperature transmitters accessible on the lookout, each custom fitted to explicit applications and conditions.

Obstruction Temperature Identifiers (RTDs), Thermocouples, and Thermistors are among the most widely recognized sensor types utilized with temperature transmitters. RTDs offer superb exactness and security, making them reasonable for basic temperature estimations in assembling processes. Thermocouples, then again, are known for their wide temperature reach and roughness, making them ideal for high-temperature applications.

Thermistors show high responsiveness and quick reaction times, making them reasonable for applications requiring fast temperature changes.

Current temperature transmitters come outfitted with cutting edge elements to upgrade execution and unwavering quality. These highlights might incorporate linearization, cold intersection remuneration,rosemount 214c rtd temperature sensor, and advanced correspondence conventions like HART or Modbus. Furthermore, a few transmitters offer programmable settings, permitting clients to modify estimation ranges, yield signals, and caution edges to suit their particular prerequisites.

Importance of Temperature Measurement in Manufacturing

Temperature estimation is a basic boundary in assembling processes across different enterprises, including drugs, food and drink, synthetic compounds, and car.

The exact control of temperature guarantees item quality, security, and administrative consistence while improving energy utilization and limiting waste. In this part, we will investigate the significance of temperature estimation in assembling and the job of temperature transmitters in guaranteeing process productivity and dependability.

In the drug business, temperature control is central for keeping up with the adequacy and security of medications and antibodies. Severe temperature observing and control all through the assembling system assist forestall item debasement and guarantee consistence with administrative principles, for example, Great Assembling Practices (GMP) and Great Appropriation Practices (Gross domestic product).

Temperature transmitters assume a fundamental part in such manner by giving precise and continuous temperature information, empowering administrators to quickly make remedial moves.

The food and refreshment industry additionally depends intensely on temperature control to guarantee item quality, newness, and security.

From food handling and stockpiling to transportation and dispersion, keeping up with the ideal temperature is vital for forestalling decay, bacterial development, and tainting. Temperature transmitters are broadly utilized in food fabricating offices to screen temperature varieties and guarantee consistence with food handling guidelines, for example, Peril Examination and Basic Control Focuses (HACCP).

In the compound business, exact temperature control is fundamental for directing different substance responses, refining cycles, and material dealing with activities. Temperature transmitters empower administrators to screen temperature changes precisely, forestall overheating or undercooling, and keep up with the ideal response rates and item quality. Besides, temperature transmitters assist with guaranteeing the security of faculty and hardware by recognizing unusual temperature conditions and setting off alerts or closures when important.

Integrating Temperature Transmitters into Manufacturing Processes

Incorporating Rosemount 214c Temperature Sensor into assembling processes requires cautious preparation, establishment, and alignment to guarantee precise and solid temperature estimation. In this segment, we will talk about the means engaged with coordinating temperature transmitters into assembling frameworks, including sensor determination, establishment contemplations, and adjustment methodology.

The most important phase in coordinating temperature transmitters is choosing the fitting sensor type in light of the application necessities, temperature reach, exactness, and ecological circumstances. RTDs are generally utilized for exact temperature estimation in modern cycles where steadiness and precision are principal. Thermocouples are liked for high-temperature applications or brutal conditions because of their roughness and wide temperature range. Thermistors are appropriate for applications requiring high responsiveness and quick reaction times, like air conditioning frameworks and clinical gadgets.

When the sensor type is chosen, the following stage is to introduce the temperature transmitter and rosemount 214c rtd temperature sensor in the ideal area inside the assembling framework. Legitimate establishment is pivotal for guaranteeing exact temperature estimation and limiting sign impedance or commotion. Factors like sensor position, mounting direction, and electrical establishing should be painstakingly considered to streamline execution and unwavering quality.

After establishment, the temperature transmitter should be adjusted to guarantee exact temperature estimation and result signal alignment. Adjustment includes looking at the transmitter's result signal against a known reference temperature utilizing an adjusted thermometer or temperature source. Any deviations or mistakes in the result sign can be amended through alignment changes or setup settings.

Enhancing Process Efficiency and Safety with Temperature Transmitters

Temperature transmitters assume a significant part in upgrading process effectiveness and security in assembling tasks. By giving exact and ongoing temperature information, these gadgets empower administrators to enhance process boundaries, forestall gear disappointments, and guarantee item quality. In this part, we will investigate how temperature transmitters add to further developing cycle proficiency and security in different assembling applications.

One of the vital advantages of temperature transmitters is their capacity to work with exact temperature control, accordingly advancing energy utilization and lessening working expenses. By keeping up with the ideal temperature setpoints inside close resiliences, makers can limit squander, further develop item consistency, and expand creation throughput. Moreover, temperature transmitters assist with distinguishing energy shortcomings and cycle bottlenecks, permitting administrators to execute designated upgrades and advancements.

One more significant part of temperature transmitter application is process wellbeing. In assembling conditions where temperature-touchy materials or perilous synthetic compounds are involved, precise temperature observing is basic for forestalling mishaps, flames, or blasts. Temperature transmitters with worked in diagnostics and caution functionalities can identify strange temperature conditions, like overheating or undercooling, and trigger programmed closures or alarms to forestall potential security risks.

Future Trends and Innovations in Temperature Transmitter Technology

As innovation keeps on developing, Rosemount 214c Temperature Sensor are continually improving to fulfill the developing needs of the assembling business. In this segment, we will investigate probably the most recent patterns and developments in temperature transmitter innovation, including remote availability, IIoT reconciliation, and high level sensor advances.

Remote temperature transmitters are acquiring ubiquity in assembling conditions because of their adaptability, versatility, and cost-adequacy. By taking out the requirement for wired associations, remote transmitters work on establishment, lessen support costs, and empower remote checking of temperature information from anyplace inside the office. In addition, remote availability considers consistent joining with Modern Web of Things (IIoT) stages, empowering prescient support, ongoing examination, and cycle streamlining.

High level sensor advancements, for example, fiber optic sensors and MEMS-based sensors, are additionally driving development in temperature transmitter plan. Fiber optic sensors offer high precision, insusceptibility to electromagnetic obstruction, and similarity with unforgiving conditions, making them ideal for testing modern applications. MEMS-based sensors, then again, are little, financially savvy, and energy-effective, empowering the improvement of conservative and low-power temperature transmitters for IoT and wearable gadgets.

All in all, temperature transmitters assume a pivotal part in the assembling business, empowering exact temperature estimation, process control, and wellbeing observing. By understanding the basics of temperature transmitters and incorporating them into assembling processes actually, makers can further develop proficiency, item quality, and administrative consistence. As innovation keeps on propelling, the eventual fate of temperature transmitter innovation holds invigorating opportunities for upgrading mechanization, network.

YOU MAY LIKE

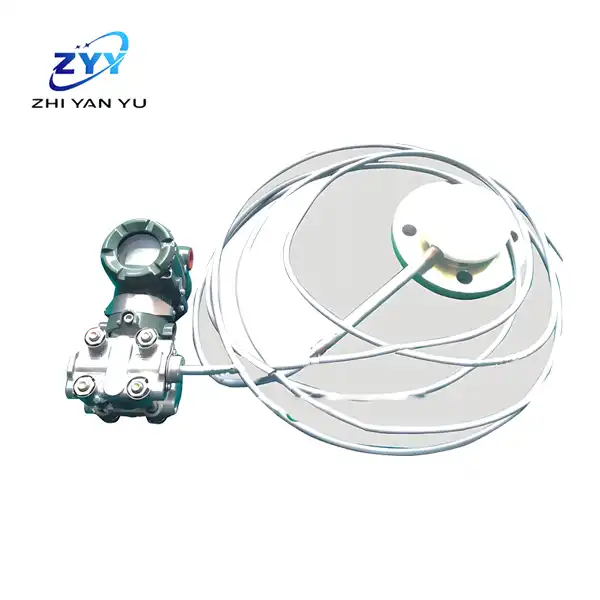

Rosemount 3051 Coplanar Pressure Transmitter

Graphical backlit display, Bluetooth® connectivity

5-year warranty, range ratio 150:1

Support multiple communication protocols

Measuring range up to 1378.95bar

Various process wetted materials

Comprehensive diagnostic capabilities

SIL 2/3 certified according to IEC 61508 etc.

The wireless update rate is adjustable and the power module has a service life of 10 years.

Rosemount 8705

Pipe Sizes: Ranges from 15-900mm (½-36in).

Lining Materials: PTFE, ETFE, PFA, polyurethane, etc.

Electrode Materials: 316L stainless steel, nickel alloys, etc.

Flange Ratings: ASME B16.5 150-2500, DIN PN 10-40, AS 2129 Table D, and AWWA C207 Table 3 D.

Submersion Protection: IP68 (recommended with sealed cable glands).

Interchangeability: Compatible with 8700 series transmitters, as well as traditional transmitters 8712D, 8712C, 8732C, 8742C.

Design: Unobstructed design to minimize maintenance and repair needs.

Fisher Valve Positioner DVC6200

Digital Communication: Compatible with digital valve diagnostics for real-time insights and predictive maintenance capabilities.

Versatility: Suitable for a wide range of applications, accommodating different types of industrial valves.

Ease of Use: Designed for simple setup and calibration, which enhances ease of operation and reduces downtime.

Precision Control: Offers precise valve positioning, significantly improving process control and efficiency.

Durability: Constructed to withstand harsh industrial environments, ensuring longevity and reduced maintenance costs.

Rosemount 214c

Output signal 4-20 mA /HART™ protocol

Rosemount™ 214C Thermocouple Temperature Sensor

Thermocouple types include J, K and T types

Thermocouple accuracy meets ASTM and IEC standards

Wide temperature coverage, -196 to 1200°C

Can withstand high frequency vibrations

Able to adapt to harsh working conditions

Yokogawa Eja310a

View More

EJX438A

Convert to 4~20mA DC current signal output.

Fast response, remote setting and monitoring, diagnostics.

High/low pressure alarm status output.

Multi-sensing technology detects abnormalities such as blockage of the pressure pipeline.

FF fieldbus type is available.

TÜV certified to SIL 2 safety