- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Differences between pressure transmitters and pressure sensors

2024-06-03 16:57:25

Differences between Pressure Transmitters and Pressure Sensors

Introduction

In the realm of industrial processes and automation, the accurate measurement and monitoring of pressure are paramount. Two indispensable devices, Rosemount 2088g Inline Pressure Transmitter and pressure sensor, play crucial roles in this arena. While both serve the fundamental purpose of measuring pressure, they possess distinct characteristics and functionalities. Understanding the differences between these devices is essential for selecting the appropriate instrument for specific applications. In this comprehensive guide, I will delve into the disparities between Rosemount 2088g Inline Pressure Transmitter and pressure sensor, elucidating their mechanisms, applications, and key differentiators.

Operating Principle

Pressure transmitters and pressure sensors operate on different principles despite their shared objective of pressure measurement. A pressure sensor typically converts applied pressure into an electrical signal, commonly through the deflection of a diaphragm or the deformation of a strain gauge. This electrical signal is then processed to provide an output indicative of the applied pressure. On the other hand, a pressure transmitter not only senses pressure but also amplifies, conditions, and transmits the signal to a control system or display unit. Thus, while pressure sensors solely generate electrical signals proportional to pressure, pressure transmitters encompass additional functionalities for signal processing and transmission.

Functionality

Pressure transmitters and pressure sensors are both significant gadgets used to gauge and screen pressure in different modern applications. While they share similitudes as far as their motivation, there are key contrasts in usefulness between the two.

Pressure sensors, otherwise called pressure checks, are gadgets that straightforwardly measure the pressure of a liquid or gas at a particular point. They normally convert the pressure signal into an electrical result, for example, voltage or flow, which can be additionally handled and deciphered by a control framework or administrator. Pressure sensors are basic in plan and are much of the time utilized in applications where just nearby pressure readings are required.

Then again, pressure transmitters are more modern gadgets that action pressure as well as have the capacity to intensify, condition, and send the pressure signal over longer distances. Pressure transmitters are outfitted with extra parts, for example, enhancers and sign molding circuits, to guarantee precise and dependable transmission of pressure information. They are generally utilized in modern computerization and control frameworks where remote observing and control of pressure are required.

One more key contrast between pressure transmitters and pressure sensors is their result signals. While pressure sensors regularly give a direct electrical result relative to the deliberate pressure, pressure transmitters offer standardized yield signals, for example, 4-20 Mama or 0-10 VDC, which are viable with most control frameworks and PLCs. This standardized result works on joining and correspondence with different gadgets in the framework.

In synopsis, pressure sensors are essential gadgets utilized for neighborhood pressure estimation, while pressure transmitters are progressed instruments intended for remote checking and control applications. Pressure transmitters offer improved usefulness, signal molding, and standardized yield signals contrasted with pressure sensors, making them reasonable for additional complex modern cycles.

Accuracy and Precision

Accuracy and precision are crucial considerations in pressure measurement applications, particularly in industries where stringent quality standards and regulatory compliance are paramount. Rosemount 2088g Inline Pressure Transmitter typically exhibits higher levels of accuracy and precision compared to pressure sensors. This is attributed to the additional calibration, compensation, and signal conditioning mechanisms incorporated into pressure transmitters. Moreover, pressure transmitters are often subjected to rigorous testing and certification processes to ensure their reliability and accuracy in demanding environments. Consequently, pressure transmitters are preferred in applications where precise and reliable pressure measurement is imperative, such as in aerospace, pharmaceutical, and semiconductor manufacturing.

Environmental Compatibility

Another significant factor distinguishing pressure transmitters from pressure sensors is their environmental compatibility and ruggedness. Pressure transmitters are engineered to withstand harsh operating conditions, including extreme temperatures, corrosive environments, and high-pressure scenarios. These devices are often encased in robust enclosures and equipped with protective features to ensure resilience against environmental factors. In contrast, while pressure sensors may offer adequate performance in controlled environments, they may lack the durability and resilience required for harsh industrial settings. Therefore, pressure transmitters are preferred for applications involving exposure to challenging environmental conditions, such as oil and gas exploration, chemical processing, and offshore drilling.

Cost Considerations

Cost considerations play a pivotal role in the selection of pressure measurement devices for industrial applications. Pressure sensors typically entail lower acquisition costs compared to pressure transmitters. This is primarily due to the simpler construction and functionality of pressure sensors, which do not incorporate advanced signal processing and communication capabilities. However, it is essential to consider the total cost of ownership, including maintenance, calibration, and system integration, when evaluating the economic feasibility of pressure sensors versus pressure transmitters. While pressure transmitters may involve higher upfront costs, their enhanced functionality, reliability, and longevity often translate into lower overall costs over the operational lifespan.

Conclusion

In conclusion, the disparities between Rosemount 2088g Inline Pressure Transmitter and pressure sensor encompass various aspects, including operating principles, functionality, accuracy, environmental compatibility, and cost considerations. While pressure sensors excel in straightforward pressure measurement applications, Rosemount 2088g Inline Pressure Transmitter offers enhanced functionality, accuracy, and resilience, making them indispensable in critical industrial processes and automation systems. Understanding the differences between these devices is essential for selecting the optimal instrument for specific applications, thereby ensuring precise, reliable, and cost-effective pressure measurement solutions.

Contact Us

For professional manufacturing solutions tailored to your requirements, contact us at lm@zyyinstrument.com. As a GMP factory with a large inventory, complete certificates, and support for OEM, we offer fast delivery, tight packaging, and comprehensive testing support. Partner with us for superior quality and reliability in pressure measurement instrumentation.

References

- "Pressure Sensor vs. Pressure Transmitter: What's the Difference?" Omega Engineering, www.omega.com/en-us/resources/pressure-sensor-vs-pressure-transmitter.

- "Choosing Between a Pressure Sensor and a Pressure Transmitter." Setra Systems, www.setra.com/blog/pressure-sensor-vs-pressure-transmitter-what-difference.

- "Pressure Transmitter vs. Pressure Sensor: What’s the Difference?" Emerson Automation Solutions, www.emerson.com/en-us/automation-solutions/pressure-transmitter-vs-pressure-sensor.

- "Pressure Transmitter vs. Pressure Sensor: Understanding the Differences." WIKA, www.wika.us/blog/pressure-transmitter-vs-pressure-sensor-understanding-differences-671.htm.

- "Differences Between Pressure Sensors and Transmitters." TE Connectivity, www.te.com/usa-en/industries/sensors/solutions/difference-between-pressure-sensor-and-transmitter.html.

YOU MAY LIKE

Fisher Valve Positioner DVC6200

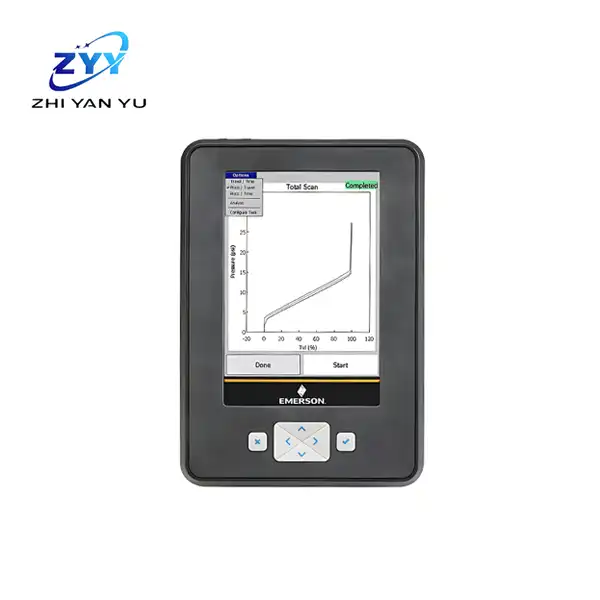

Emerson Ams Trex Device Communicator

Improve reliability and withstand harsh conditions assess safety

Microprocessor 800 MHZ ARM Cortex A8/NXP

Built-in flash memory 2 GB NAND and 32 GB extended flash memory RAM 512 MB DDR3 SDRAM

Display 5.7-inch (14.5 cm) color VGA resistive touch screen

Rosemount 2051TA Pressure Transmitter

Range ratio up to 50:1 supports 4-20mA and 1-5V HART

Gauge pressure/absolute pressure up to 4000psig/a

Wetted material: 316L SST, alloy C276

Basic diagnostic function certification: NSF, NACE

Lightweight and compact design

Yokogawa Eja310a

View More

Yokogawa Eja430e

Suitable for measuring liquid, gas or steam pressure.

Output 4~20mA DC current signal.

Fast response, remote setup and monitoring.

Diagnostic function to detect blockage of the pressure pipeline or abnormality of the heating system.

FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.