- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does A Rosemount Pressure Transmitter Work

2024-04-15 15:33:40

Rosemount pressure transmitters are among the most widely used devices in the world of industrial process instrumentation. They are recognized for their reliability and precision in measuring fluid and gas pressures in various industries, such as oil and gas, pharmaceuticals, and water treatment. This blog provides an in-depth look into how a Rosemount pressure transmitter operates, ensuring that technicians and engineers understand the principles and components that allow these transmitters to function effectively.

What Are the Main Components of a Rosemount Pressure Transmitter?

Understanding the main components of a Rosemount pressure transmitter is essential for comprehending how the device measures pressure and converts it into a usable signal.

Pressure Sensor Module

The pressure sensor module is the core component responsible for detecting the pressure of the process fluid or gas. It typically contains a piezoresistive or capacitive sensor, which reacts to changes in pressure by altering its electrical properties. The sensor detects this change and converts it into an electrical signal.

Transmitter Electronics

The transmitter electronics process the raw signal from the sensor and convert it into a standardized output, usually 4-20 mA or a digital protocol like HART. This circuit often includes signal conditioning, filtering, and amplification stages to ensure that the final output is accurate and stable.

Housing and Process Connections

The transmitter's housing protects the internal components from harsh environments. Process connections link the transmitter to the pipeline or vessel, ensuring accurate and reliable transmission of process pressure to the sensor.

How Does a Rosemount Pressure Transmitter Measure and Transmit Pressure Data?

A Rosemount pressure transmitter operates through a sequence of steps that involve sensing, signal processing, and data transmission. Each of these steps plays a crucial role in ensuring accurate pressure measurements.

Sensing Pressure Changes

Pressure Application: When process pressure is applied to the pressure sensor module, the sensing element inside reacts to the mechanical force exerted by the process fluid or gas.

Sensor Response: Depending on the type of sensor (piezoresistive or capacitive), the sensing element undergoes a physical change. In a piezoresistive sensor, the resistance changes, while in a capacitive sensor, the capacitance varies due to the applied pressure.

Electrical Signal Generation: The mechanical change is translated into an electrical signal, representing the magnitude of the applied pressure.

Signal Processing

Signal Conditioning: The raw electrical signal is conditioned to filter out noise and adjust the signal level for further processing.

Amplification and Conversion: The conditioned signal is amplified and converted into a form suitable for transmission, usually a 4-20 mA current signal or a digital communication protocol like HART.

Temperature Compensation: Compensation circuits adjust the signal based on the operating temperature to ensure consistent accuracy.

Data Transmission

Output Signal Generation: The processed signal is converted to the final output, either in analog form (4-20 mA current loop) or digital form (using protocols like HART, FOUNDATION Fieldbus, or Modbus).

Remote Communication: Digital protocols enable the transmitter to communicate directly with control systems or handheld calibrators for configuration, monitoring, and diagnostics.

How Do Different Types of Rosemount Pressure Transmitters Work?

Rosemount manufactures various types of pressure transmitters, each designed for specific applications and pressure ranges. Here is how each type operates.

Differential Pressure Transmitter

Working Principle: Measures the difference in pressure between two points using two separate process connections. The sensor detects the pressure difference and converts it into an electrical signal.

Applications: Commonly used for flow measurement in pipes, tank level monitoring, and filter condition assessment.

Absolute Pressure Transmitter

Working Principle: Measures the absolute pressure of a fluid or gas relative to a perfect vacuum (zero reference pressure). It has a single process connection, and the sensor is sealed with a reference vacuum.

Applications: Useful for vacuum system monitoring and applications where atmospheric pressure variations could impact measurements.

Gauge Pressure Transmitter

Working Principle: Measures pressure relative to atmospheric pressure. The sensor detects the difference between the process pressure and the ambient pressure, using a single process connection.

Applications: Ideal for applications like pump monitoring, where the pressure is referenced against the ambient atmospheric pressure.

Conclusion

A Rosemount pressure transmitter is a highly engineered device that incorporates advanced sensing and signal processing technologies to provide accurate and reliable pressure measurements in demanding industrial environments. By understanding the components and the measurement principles of different types of pressure transmitters, technicians can better select and maintain the appropriate device for their specific application.

References

Rosemount Product Manual (2023). "Pressure Transmitter Fundamentals."

Process Instrumentation Review (2022). "Understanding the Components of a Pressure Transmitter."

Calibration Technology Portal (2023). "How Pressure Sensors Operate in Different Transmitter Types."

Instrumentation Standards Association (2022). "Application Guidelines for Differential, Gauge, and Absolute Pressure Transmitters."

Process Measurement Magazine (2021). "Data Transmission Technologies for Modern Pressure Transmitters."

Calibration and Measurement Journal (2023). "Key Considerations in Pressure Transmitter Selection."

Pressure Technology Forum (2022). "Temperature Compensation and Signal Processing in Pressure Transmitters."

Instrumentation Insights (2021). "Choosing Between Analog and Digital Output Pressure Transmitters."

Field Calibration Workshop (2022). "Remote Communication and Diagnostics in Pressure Transmitters."

Process Engineering Blog (2023). "Maintaining Accuracy Through Proper Installation of Pressure Transmitters."

YOU MAY LIKE

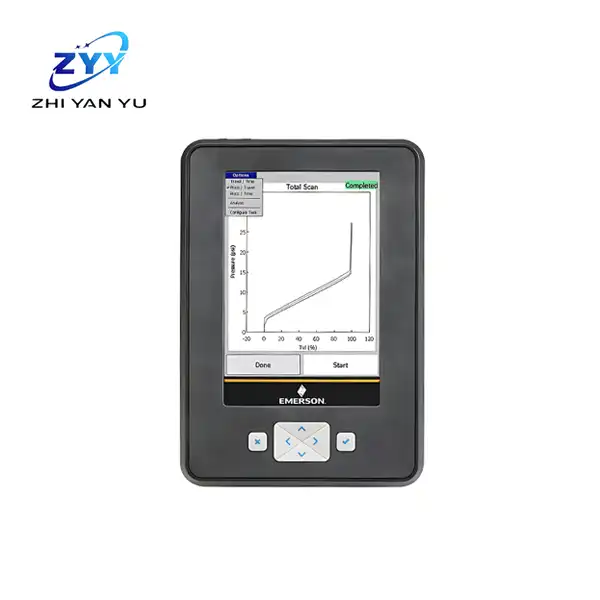

AMS Trex device communicator

Rosemount™ 3144P temperature transmitter

Rosemount 2051CD differential pressure transmitter

Yokogawa EJA120E differential pressure transmitter

Yokogawa EJX120A differential pressure transmitter