- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pressure transmitter maintenance and preventive care

2024-07-24 16:35:38

Pressure Transmitter Maintenance and Preventive Care

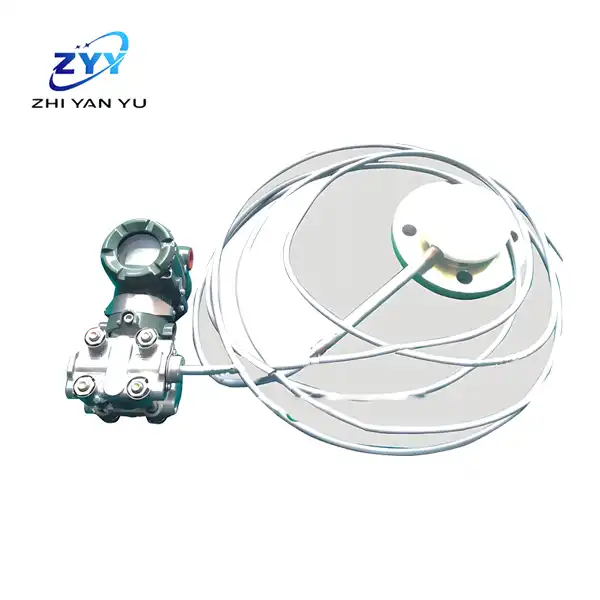

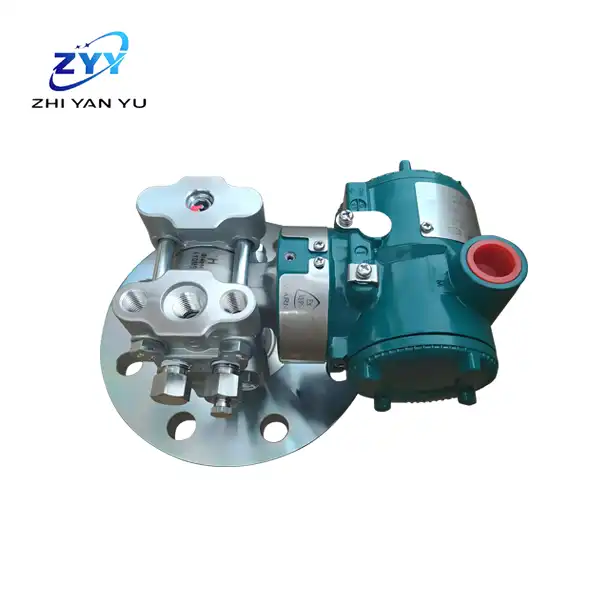

Maintenance and preventive care are fundamental parts of guaranteeing the ideal presentation and life span of Rosemount 2088g Inline Pressure Transmitters. These gadgets assume a basic part in different businesses, checking and controlling pressure levels in frameworks to keep up with functional proficiency and security.

Ordinary maintenance schedules are important to distinguish and resolve any likely issues before they grow into exorbitant issues. This incorporates investigating the transmitter for indications of wear, consumption, or harm, as well as actually taking a look at the respectability of seals and associations. Also, alignment checks ought to be led intermittently to guarantee exact pressure readings.

Preventive care measures include carrying out systems to limit mileage on the transmitter and draw out its life expectancy. This might incorporate introducing defensive measures, for example, gatekeepers or nooks to safeguard the gadget from natural risks or mechanical harm. Appropriate establishment procedures, including guaranteeing legitimate arrangement and mounting, are likewise vital for ideal execution and unwavering quality.

Consistently booked maintenance spans ought to be laid out in light of the particular working circumstances and climate in which the pressure transmitter works. This might shift relying upon elements like temperature vacillations, openness to brutal synthetics, or high-pressure conditions.

Moreover, appropriate documentation of maintenance exercises, including investigation reports, adjustment records, and any fixes or substitutions performed, is fundamental for detectability and consistence with administrative standards.

Understanding Pressure Transmitters

Pressure transmitters are fundamental instruments used in different modern cycles to precisely quantify and communicate pressure information. These gadgets assume a basic part in checking and controlling pressure levels in frameworks like pipelines, tanks, and hardware across numerous businesses, including oil and gas, substance, drug, and assembling.

At its center, a Rosemount 2088g Inline Pressure Transmitter comprises of a detecting component, signal molding hardware, and a correspondence interface. The detecting component, frequently a stomach or bourdon tube, twists in light of applied pressure, producing an electrical sign relative to the pressure applied. This sign is then handled and enhanced by the sign molding hardware to guarantee precision and security.

One critical part of understanding pressure transmitters is appreciating the different kinds accessible, including outright, check, and differential pressure transmitters. Outright pressure transmitters measure pressure comparative with an ideal vacuum, while check pressure transmitters measure pressure comparative with air pressure. Differential pressure transmitters, then again, measure the distinction in pressure between two focuses in a framework.

Moreover, adjustment and establishment are urgent contemplations while working with pressure transmitters. Appropriate adjustment guarantees the exactness and unwavering quality of pressure estimations, while right establishment, including legitimate mounting and fixing, forestalls errors and possible harm.

Notwithstanding their essential capability of pressure estimation, present day pressure transmitters frequently come outfitted with cutting edge elements like advanced correspondence conventions, self-diagnostics, and remote observing abilities, upgrading their ease of use and productivity in modern applications.

Routine Inspection and Calibration

Normal review and alignment are central to keeping up with the exactness and dependability of pressure transmitters, guaranteeing ideal execution in modern applications. The course of investigation and adjustment includes a few basic moves toward distinguish any possible issues and confirm the transmitter's precision.

To start the investigation, outwardly analyze the pressure transmitter for any noticeable indications of harm, corruption, or anomalies. This incorporates checking for consumption, releases, actual harm to the packaging, and it are secure to guarantee all associations. Any irregularities saw during this visual examination ought to be addressed speedily to forestall further weakening and keep up with functional honesty.

Following the visual assessment, the alignment interaction starts with checking the exactness of the pressure transmitter's estimations. This is normally finished by contrasting the readings of the transmitter with those of an aligned reference instrument, for example, a pressure calibrator or standard pressure check. The correlation ought to incorporate a scope of pressure values pertinent to the transmitter's planned application.

During adjustment, it's fundamental to comply to the maker's suggested systems and rules, as well as significant industry standards and guidelines. This might include changing the transmitter's result sign or settings to line up with the reference instrument's readings. Adjustment methodology ought to be performed via prepared faculty with the important abilities and hardware to guarantee exactness and accuracy.

Moreover, it's fitting to lay out a normal adjustment plan in light of the transmitter's utilization, ecological circumstances, and criticality of the application. This guarantees that the transmitter stays inside OK exactness limits after some time and gives dependable information to handle control and checking.

Documentation of adjustment exercises is likewise essential for recognizability and quality confirmation purposes. This incorporates keeping up with records of alignment dates, results, changes made, and any deviations from anticipated values. These records act as a source of perspective for the end goal of reviewing and exhibit consistence with administrative necessities.

Cleaning and Environmental Considerations

Legitimate cleaning methodology are fundamental for protecting the uprightness and usefulness of Rosemount 2088g Inline Pressure Transmitters, especially while working in brutal or testing conditions. Compelling cleaning rehearses help to eliminate soil, oil, flotsam and jetsam, and different foreign substances that can collect on the outside surfaces of the transmitter, possibly undermining its presentation and exactness.

While cleaning pressure transmitters, it's essential to utilize gentle solvents or cleaning specialists that are viable with the materials utilized in the development of the transmitter. Try not to utilize brutal synthetics or grating cleaners that could harm the delicate parts or defensive coatings of the transmitter. All things being equal, pick delicate cleaning arrangements that can really eliminate pollutants without actually hurting.

Start by investigating the outside of the pressure transmitter for any noticeable indications of soil, oil development, or other flotsam and jetsam. Give close consideration to regions where pollutants are probably going to aggregate, like around the connectors, lodging creases, and mounting sections. Utilize a delicate fabric or wipe hosed with the picked cleaning answer for tenderly wipe away any surface soil or grime.

For obstinate or difficult to-eliminate impurities, you might have to utilize a delicate shuddered brush or q-tip to scour the impacted regions tenderly. Be careful not to apply over the top power or scouring, as this might actually harm the transmitter's sensitive parts or defensive coatings.

As well as cleaning the outside surfaces, it's vital to consider natural factors that might affect the exhibition and life span of the pressure transmitter. Factors, for example, temperature vacillations, high dampness levels, openness to destructive substances, and airborne particles can all add to debasement after some time.

To relieve the impacts of these ecological variables, consider executing preventive measures, for example, introducing defensive nooks or hindrances, carrying out normal maintenance timetables, and checking natural circumstances intently. These proactive measures can assist with expanding the life expectancy of the pressure transmitter and guarantee dependable execution in testing working conditions.

Troubleshooting Common Issues

Regardless of customary maintenance endeavors, pressure transmitters can at times encounter gives that require investigating to recognize and redress the issue. Among the normal issues experienced are errors in readings, signal float, and electrical flaws, which can unfavorably influence the exhibition and unwavering quality of the transmitter.

While investigating pressure transmitter issues, it's significant in any case an orderly methodology, beginning with a visual examination of the gadget. Check for any free associations, harmed wiring, or apparently flawed parts that might be adding to the issue. Give specific consideration to the electrical associations and guarantee they are secure and appropriately situated.

Then, it's fitting to check the adjustment of the pressure transmitter to decide whether any mistakes in the readings are available. This should be possible by looking at the transmitter's result against an adjusted reference instrument or standard pressure check. In the event that disparities are identified, changes might should be made to recalibrate the transmitter and reestablish precision.

In situations where sign float is noticed, it very well might be important to explore potential causes like natural variables, temperature vacillations, or changes in process conditions. Natural circumstances can fundamentally affect the exhibition of pressure transmitters, so it's fundamental to evaluate whether any variables are impacting signal strength.

On the off chance that investigating endeavors neglect to determine the issue or on the other hand in the event that there are worries about the trustworthiness of the transmitter, counseling the maker's documentation or enroll the help of a certified technician might be important. Producer rules and specialized help assets can give important experiences into explicit investigating methods and likely answers for settling complex issues.

Long-Term Storage and Spare Parts

Legitimate groundwork for Rosemount 2088g Inline Pressure Transmitters that are not being used or require long haul stockpiling is fundamental to forestall harm and decay. To guarantee ideal protection, a few key advances ought to be followed.

First and foremost, completely clean the transmitter to eliminate any aggregated garbage, residue, or foreign substances. Utilize proper cleaning specialists and methods appropriate for the transmitter's materials to abstain from causing harm during the cleaning system.

Then, eliminate any batteries or power sources from the transmitter. This forestalls the gamble of consumption or spillage after some time, which can harm the inward parts and compromise usefulness.

Once cleaned and depowered, putting away the transmitter in a reasonable environment is significant. Pick a dry, temperature-controlled area to limit the gamble of dampness development or outrageous temperature variances, the two of which can unfavorably influence the transmitter's exhibition and life expectancy.

Think about utilizing defensive bundling or cases to safeguard the transmitter from actual harm during capacity. This is especially significant on the off chance that the transmitter is being put away close by other gear or in a possibly risky climate.

Notwithstanding legitimate capacity conditions, keeping a stock of extra parts is strongly suggested. This guarantees that any maintenance or fix needs that might emerge during capacity or when the transmitter is returned to administration can be speedily tended to. Normal extra parts might incorporate seals, gaskets, O-rings, and electronic parts.

Routinely examine the put away transmitter to check for indications of harm, consumption, or disintegration. Assuming any issues are recognized, make a proper move to address them quickly to forestall further harm and guarantee the transmitter stays in ideal condition for sometime later.

Contact Us

With regards to top-level Rosemount 2088g Inline Pressure Transmitters and far reaching support, our regarded producing organization stands out as a confided in decision. Flaunting a GMP-confirmed plant, a huge stock, and OEM capacities, we focus on satisfying your modern instrumentation prerequisites with greatness.

Our obligation to quality beginnings with the choice of premium materials and adherence to thorough assembling standards. Each pressure transmitter goes through fastidious testing and review to guarantee ideal execution and dependability in different modern conditions.

At the center of our tasks is a best in class GMP-confirmed processing plant furnished with state of the art innovation and high level hardware. This office empowers us to keep up with exact command over the creation interaction, from unrefined substance procurement to end result gathering.

With a broad stock of pressure transmitters, we offer a large number of models to suit different applications and determinations. Whether you require differential pressure transmitters, outright pressure transmitters, or measure pressure transmitters, we have the answer for address your issues.

Moreover, our OEM capacities permit us to alter pressure transmitters as indicated by your particular necessities, guaranteeing consistent reconciliation into your frameworks and gear.

Notwithstanding our unrivaled items, we offer unmatched help to our clients. Our group of proficient experts is committed to helping you constantly, from item choice to specialized help and after-deals administration.

To become familiar with our extensive item contributions and how we can uphold your business, we welcome you to reach us at lm@zyyinstrument.com. Our accomplished agents are prepared to examine your necessities and give fitted answers for assist you with accomplishing your modern instrumentation objectives.

In rundown, for proficient grade pressure transmitters and solid help, our legitimate assembling organization is the accomplice you can trust. With our GMP-affirmed production line, broad stock, and OEM capacities, we are focused on surpassing your assumptions and adding to your outcome in the modern area.

References:

- "Pressure Transmitter Maintenance Best Practices" - Emerson Automation Solutions

- "Calibration Procedures for Pressure Transmitters" - Fluke Corporation

- "Environmental Effects on Pressure Transmitter Performance" - ISA Transactions

- "Troubleshooting Guide for Pressure Transmitters" - WIKA Instrument Corporation

- "Long-Term Storage Recommendations for Industrial Instruments" - Yokogawa Electric Corporation

YOU MAY LIKE

Rosemount 3051CD Coplanar Pressure Transmitter

Rosemount 2090F

Graphical backlit display, Bluetooth® connectivity

5-year warranty, range ratio 150:1

Support multiple communication protocols

Measuring range up to 1378.95bar

Various process wetted materials

Comprehensive diagnostic capabilities

SIL 2/3 certified according to IEC 61508 etc.

The wireless update rate is adjustable and the power module has a service life of 10 years.

EJX438A

Convert to 4~20mA DC current signal output.

Fast response, remote setting and monitoring, diagnostics.

High/low pressure alarm status output.

Multi-sensing technology detects abnormalities such as blockage of the pressure pipeline.

FF fieldbus type is available.

TÜV certified to SIL 2 safety

Honeywell Pressure Transmitter St700

The output signal is usually 4-20mA.

Signal is linearly related to pressure.

The control panel adjusts the sensitive components.

Provides output signal calibration options.

Pressure testing ensures resistance to extreme pressures.

Rosemount 2051CD

Communication protocols: 4-20mA HART®, WirelessHART®, FOUNDATION™ Fieldbus, PROFIBUS®, 1-5V Low Power HART®

Transmitter connections: welded, serviceable process connections, flanged

Process wetted materials: 316L SST, Alloy C-276, Tantalum

Diagnostics Basic Diagnostics Certifications: SIL 2/3 certification based on IEC 61508, NACE® certification, hazardous location certification

Yokogawa EJA210E

Measure static pressure with built-in display or remote monitoring.

Fast response, remote setting, diagnostics and optional pressure alarm output.

Multi-sensing technology detects abnormalities such as blockage in the pressure pipeline.

FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.