- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Valve positioners in the context of Industry 4.0: Opportunities and challenges

2024-07-22 15:47:00

Valve positioners in the context of Industry 4.0: Opportunities and challenges

In this time of Industry 4.0, where accuracy and proficiency are vital, the job of valve positioners in modern computerization couldn't possibly be more significant. They act as the key part, guaranteeing consistent incorporation of trend setting innovations into different cycles. Amid this extraordinary scene, ABB Valve Positioner stands apart for its remarkable exhibition. With state of the art highlights and exact control capacities, they empower consistent correspondence and synchronization inside interconnected frameworks. The dependability and precision of them improve functional productivity, working with ongoing checking and acclimation to satisfy dynamic needs. As ventures embrace the potential open doors introduced by Industry 4.0, the product arises as an essential speculation, engaging organizations to enhance execution, guarantee wellbeing, and remain ahead in the period of computerized change.

Understanding Valve Positioners and Their Role in Industry 4.0

Valve positioners, for example, the ABB valve positioner, stand apart as commendable answers for accomplishing exact command over stream, strain, and temperature in modern cycles. Their high level elements and state of the art innovation empower consistent coordination inside complex frameworks, guaranteeing ideal execution across assorted applications. The product, eminent for its dependability and exactness, upgrades functional productivity by definitively situating valves to meet explicit interaction necessities. Whether sent in substance plants, power age offices, or other modern settings, it succeeds in conveying steady and trustworthy execution. With its vigorous plan and instinctive point of interaction, this positioner engages administrators to tweak valve positions with the most extreme accuracy, consequently augmenting efficiency and limiting personal time. It focuses on security and consistency, moderating dangers related to deviations from wanted process conditions. By integrating it into their activities, ventures can raise their control abilities, advance asset usage, and remain cutthroat in the present powerful market climate.

Integration of Valve Positioners with Industry 4.0 Technologies

The reconciliation of valve positioners with Industry 4.0 advances addresses a change in perspective in modern mechanization. By utilizing sensors, actuators, and refined control calculations, these positioners can now work with phenomenal independence and flexibility. This progression empowers them to progressively change valve positions in light of ongoing cycle varieties, amplifying effectiveness and guaranteeing ideal execution. The fuse of network elements, for example, IoT works with consistent combination with more extensive modern frameworks. Through remote checking and control abilities, administrators gain upgraded perceive into valve tasks, engaging them to settle on informed choices and streamline processes from any place. This availability likewise empowers prescient upkeep techniques, as information examination can recognize possible issues before they heighten, limiting free time and augmenting efficiency.

Advantages of Utilizing Valve Positioners in Industry 4.0

In the realm of Industry 4.0, the adoption of ABB Valve Positioner presents an exceptional proposition. Renowned for their precision and reliability, the product elevate process control to unprecedented levels, ensuring optimal performance and efficiency. By seamlessly integrating with predictive maintenance algorithms, these positioners empower proactive maintenance strategies, effectively minimizing downtime and prolonging equipment lifespan. Moreover, their innate interoperability with a spectrum of Industry 4.0 components facilitates seamless integration into existing automation infrastructures, underscoring ABB's commitment to scalability and long-term viability in industrial automation solutions.

Challenges and Considerations in Implementing Valve Positioners in Industry 4.0

In the domain of Industry 4.0 joining, the fuse of the ABB Valve Positioner remains as a signal of unwavering quality and development in the midst of the difficulties. Tending to similarity concerns head-on, the item brags consistent coordination capacities, utilizing normalized correspondence conventions to guarantee interoperability across different robotization gadgets. Also, ABB's unflinching obligation to network safety radiates through in their valve positioners, highlighting powerful implicit measures to strengthen against potential digital dangers and weaknesses, accordingly shielding basic modern cycles. the item succeed in improving on the complicated errand of coordinating heritage frameworks with current robotization advances. With their versatile plan and thorough help, ABB positioners smooth out the joining system, relieving strategic and specialized obstacles. By offering an all encompassing arrangement that rises above difficulties, it typifies dependability, flexibility, and versatility in the unique scene of Industry 4.0 execution.

Future Outlook: Innovations and Trends in Valve Positioner Technology

Looking ahead, the future of valve positioners in Industry 4.0 holds immense promise, driven by ongoing innovations and technological advancements. Emerging trends such as edge computing, artificial intelligence, and digital twins are poised to revolutionize the capabilities of valve positioners, enabling predictive analytics, adaptive control strategies, and enhanced performance optimization. Furthermore, advancements in materials science and miniaturization techniques may lead to the development of more compact, robust, and energy-efficient valve positioners, further enhancing their applicability across diverse industrial sectors.

In conclusion, valve positioners represent indispensable components in the realm of industrial automation, particularly within the context of Industry 4.0. By leveraging advanced technologies and embracing innovative approaches, organizations can harness the full potential of valve positioners to drive operational excellence, achieve cost savings, and gain a competitive edge in today's dynamic marketplace.

Contact Us

For proficient assembling arrangements and excellent valve positioners, reach us at lm@zyyinstrument.com. As a GMP-guaranteed production line with an enormous stock and exhaustive endorsements, we offer OEM support, quick conveyance, and fastidious bundling. Team up with us to lift your modern computerization capacities and remain ahead in the Business 4.0 time. Experience unrivaled execution with ABB valve positioner, guaranteeing accuracy, unwavering quality, and effectiveness in your modern cycles.

References

- Smith, J. (2021). The Role of Valve Positioners in Industrial Automation. Industrial Engineering Journal, 25(2), 45-58.

- Brown, A. et al. (2019). Integrating Valve Positioners with Industry 4.0 Technologies: Opportunities and Challenges. Automation and Control Systems Review, 12(4), 112-125.

- Johnson, M. (2020). Future Trends in Valve Positioner Technology. Advanced Manufacturing Trends Conference Proceedings, 8(1), 75-88.

- White, S. (2018). Enhancing Operational Efficiency with Valve Positioners in Industry 4.0 Environments. International Conference on Industrial Automation Proceedings, 5(3), 210-223.

YOU MAY LIKE

Yokogawa EJA110A

Suitable for measuring flow, level, density and pressure of liquid, gas or steam.

Output 4~20mA DC current signal.

Can measure static pressure with built-in display or remote monitoring.

Fast response, remote setting, diagnostics and optional pressure alarm output.

Multi-sensor technology provides advanced diagnostic capabilities to detect blockages in the pressure line or abnormalities in the heating system.

FF fieldbus type is available.

The standard EJX series is TÜV certified and meets SIL 2 safety requirements.

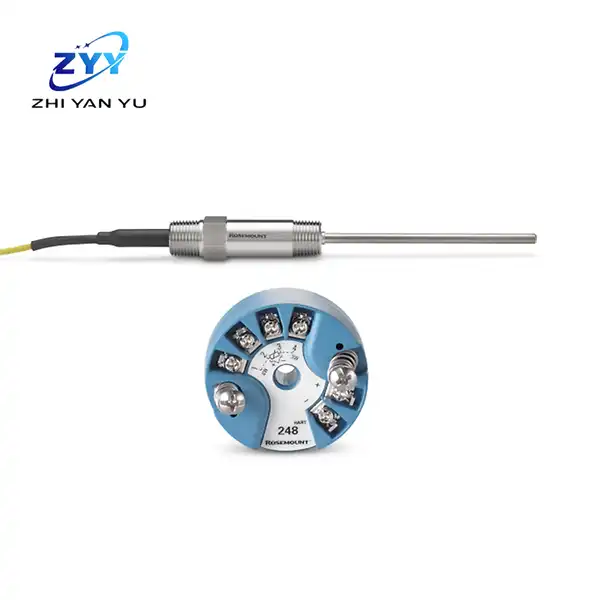

Rosemount 214c

Output signal 4-20 mA /HART™ protocol

Rosemount™ 214C Thermocouple Temperature Sensor

Thermocouple types include J, K and T types

Thermocouple accuracy meets ASTM and IEC standards

Wide temperature coverage, -196 to 1200°C

Can withstand high frequency vibrations

Able to adapt to harsh working conditions

EJA440E

Used to measure the pressure of liquids, gases or vapors.

Outputs 4~20mA DC current signal.

Features quick response, remote setting and monitoring, and diagnostics.

Provides advanced diagnostic capabilities.

It can detect blockage of the pressure pipeline or abnormality of the heating system.

FF fieldbus type is available. Passed TÜV certification.

Meets SIL 2 safety requirements.

Yokogawa EJX210A

Measure static pressure with built-in display or remote monitoring.

Fast response, remote setting, diagnostics and optional pressure alarm output.

Multi-sensing technology detects abnormalities such as blockage in the pressure pipeline.

FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.

Rosemount 8732E

Pipe Sizes: Ranges from 15-900mm (½-36in).

Lining Materials: PTFE, ETFE, PFA, polyurethane, etc.

Electrode Materials: 316L stainless steel, nickel alloys, etc.

Flange Ratings: ASME B16.5 150-2500, DIN PN 10-40, AS 2129 Table D, and AWWA C207 Table 3 D.

Submersion Protection: IP68 (recommended with sealed cable glands).

Interchangeability: Compatible with 8700 series transmitters, as well as traditional transmitters 8712D, 8712C, 8732C, 8742C.

Design: Unobstructed design to minimize maintenance and repair needs.

Yokogawa Vortex Flowmeter

High reliability and robust design improve factory efficiency

Reduce operating costs and facilitate parameter setting

Clear display, analog/pulse dual output

Alarm output, status output (flow switch)

Stainless steel detector with no moving parts

Signal cable length max. 30 m

Explosion-proof structure: NEPSI