- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

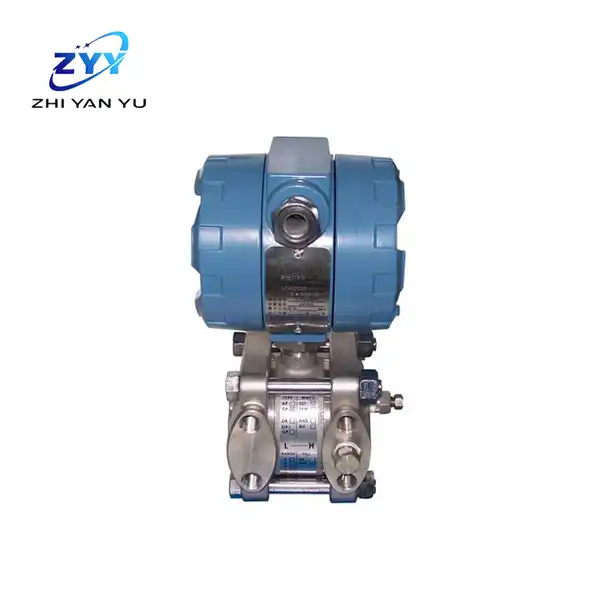

Rosemount 1151ap Absolute Pressure Transmitter

Range ratio up to 50:1 supports 4-20mA and 1-5V HART

Gauge pressure/absolute pressure up to 4000psig/a

Wetted material: 316L SST, alloy C276

Basic diagnostic function certification: NSF, NACE

Lightweight and compact design

Rosemount 1151ap Absolute Pressure Transmitter Product Overview

The Rosemount 1151ap Absolute Pressure Transmitter is a robust and reliable device designed for precise measurement of absolute pressure in various industrial applications. This transmitter is part of the esteemed Rosemount 1100 series, known for its accuracy, reliability, and long-lasting performance. With a commitment to continuous improvement, the 1151AP offers advanced technology and field-proven performance, ensuring accurate and consistent pressure readings.

Shaanxi Zhiyanyu is a professional supplier of high-quality process control testing and measuring instruments. We specialize in selling various transmitters, including pressure transmitters, temperature transmitters, flow transmitters, liquid level meters, flow meters, pressure gauges, sensors, valve positioners and other instruments. Widely used in chemical industry, petroleum, papermaking, electric power, city gas, environmental protection, water treatment and other fields. Most of our products are exported to the Middle East, Asia, Africa and America. It also enjoys a high reputation at home and abroad. We can provide selection quotations for more products of this brand, which can best meet your needs!

Product Features

High Accuracy: The 1151AP boasts a reference accuracy of 0.075%, ensuring precise pressure measurements that are crucial for process control and optimization.

Two-Year Stability: With a two-year stability of 0.1%, this transmitter maintains its accuracy over time, reducing the need for frequent recalibrations and minimizing maintenance costs.

Rangeability: The 1151AP's 50:1 rangeability allows for flexibility in measuring a wide range of pressures, reducing the need for multiple transmitters.

Modular Design: The transmitter's modular design allows for interchangeable mechanical and electrical components, providing backward and forward compatibility for easy upgrades and replacements.

Smart Electronics: The Smart Electronics option offers digital communication capabilities, enabling remote configuration, monitoring, and diagnostics, enhancing the overall efficiency of the system.

Technical Specifications

| Specification | Details |

|---|---|

| Measurement Range | -40 to 220 °F (–40 to 104 °C) for Silicone Fill Sensor; 0 to 160 °F (–18 to 71 °C) for Inert Fill Sensor |

| Output Options | 4–20 mA with Digital Signal based on HART Protocol (Smart), 4–20 mA, Linear with Input |

| Accuracy | ±0.075% of calibrated span |

| Stability | ±0.1% of calibrated span for 2 years |

| Temperature Effect | Zero Error = ±0.2% URL per 100 °F; Total Error = ±(0.2% URL + 0.18% of calibrated span) per 100 °F |

| Power Supply | 12 to 45 V dc with no load for Smart/Analog Output; 5 to 12 V dc for Low Power Output |

| Current Consumption | 1.5 mA dc for Low Power Output Code L; 2.0 mA dc for Low Power Output Code M |

| Operating Pressure | 0 psia to the URL |

| Overpressure Limits | 0 psia to 2,000 psia (0 to 13790 kPa) for DP; 0 psia to 4,500 psia (0 to 31027 kPa) for HP |

| Humidity Limits | 0 to 100% relative humidity |

| Process Connections | 1/4–18 NPT on 2.125-in. (54-mm) centers for Ranges 3, 4, and 5; 1/4–18 NPT on 2.188-in. (56-mm) centers for Ranges 6 and 7; 1/4–18 NPT on 2.250-in. (57-mm) centers for Range 8 |

| Weight | 12 lb (5.4 kg) for AP, DP, GP, and HP transmitters, excluding options |

Product Features

Advanced Diagnostics: The Rosemount 1151ap Absolute Pressure Transmitter's smart electronics provide advanced diagnostics, allowing for predictive maintenance and real-time monitoring of the transmitter's health.

User-Friendly Interface: The HART protocol enables easy configuration and monitoring through a standard HART communication device.

Rugged Construction: The transmitter is built with high-quality materials to withstand harsh environments and ensure long-term reliability.

Versatile Mounting Options: Available with various mounting brackets for easy integration into existing systems.

Customizable Outputs: The transmitter can be configured to provide linear or square root outputs, as well as low-power options, to suit specific application requirements.

Applications

Oil and Gas Industry: The Rosemount 1151ap Absolute Pressure Transmitter is ideal for monitoring wellhead pressures, pipeline pressures, and other critical points in the oil and gas extraction, production, and transportation processes.

Chemical Processing: In the chemical industry, the transmitter's accuracy and stability are essential for controlling reactions and ensuring product quality.

Power Generation: Accurate pressure measurement is critical in power plants for monitoring steam and turbine pressures.

Water and Wastewater Treatment: The 1151AP helps in maintaining optimal pressure levels in water distribution networks and monitoring treatment processes.

Food and Beverage: For ensuring hygiene and maintaining process integrity in food and beverage manufacturing, the 1151AP provides reliable pressure readings.

Technical Support and Services

Shaaxi ZYY offers comprehensive technical support and services to ensure that our customers receive the best possible experience with the absolute pressure transmitter. Our team of experts is ready to assist with product selection, installation guidance, and troubleshooting. We also provide training sessions and ongoing support to ensure that your operations run smoothly and efficiently.

Certifications

The Rosemount 1151AP Absolute Pressure Transmitter is certified by various international standards, including:

CNAS (China National Accreditation Service for Conformity Assessment)

ROHS (Restriction of Hazardous Substances)

ExNEPSI (National exploration Safety Certification for Electrical Equipment)

ISO 9001 (International Organization for Standardization for quality management systems)

MA (Meter Approval)

Installation Steps

Preparation:

Ensure that all installation tools and necessary accessories are available.

Verify that the transmitter's specifications match the application requirements.

Check the transmitter's packaging for any damage that may have occurred during shipping.

Mounting:

Choose an appropriate location for the transmitter that provides easy access for future maintenance and is free from extreme temperatures and vibrations.

Mount the transmitter using the appropriate mounting bracket (pipe mount, panel mount, etc.) as per the transmitter's documentation.

Ensure the absolute pressure transmitter is securely fastened to prevent any movement that could affect pressure readings.

Connection:

Connect the transmitter's process connections to the process piping, ensuring that the high-pressure side (process side) and the low-pressure side (atmospheric side) are correctly identified and connected.

If applicable, install the appropriate diaphragm seal or other pressure sensing accessories.

Connect the transmitter's electrical connections to the control system, ensuring proper polarity and adherence to electrical codes.

Wiring:

Wire the transmitter according to the wiring diagram provided in the manual, taking care to avoid any strain on the wires.

If the transmitter is equipped with HART communication, ensure that the HART communication wires are correctly connected and grounded.

Leak Testing:

Perform a leak test on the pressure connections to ensure that there are no leaks which could affect the accuracy of the readings.

Zeroing and Spanning:

Zero the transmitter by applying atmospheric pressure to the low-pressure side and using the zero adjustment feature.

Span the transmitter by applying a known pressure to the high-pressure side and adjusting the span as necessary.

System Check:

Once installed, perform a system check to ensure that the transmitter is functioning correctly and providing accurate readings.

Check the transmitter's output signal against a known pressure to verify accuracy.

Documentation:

Record the installation details, including location, date, and any configuration settings made during installation.

Maintenance Guide

Regular Inspection:

Regularly inspect the transmitter for any signs of damage, corrosion, or wear that could affect performance.

Cleaning:

If necessary, clean the transmitter's external surfaces with care, using non-abrasive materials and solvents compatible with the transmitter's materials.

Diaphragm Replacement:

If the diaphragm or other pressure sensing components need replacement, follow the manufacturer's guidelines for replacement procedures.

Calibration:

Periodically calibrate the transmitter to maintain its accuracy. The interval between calibrations will depend on the application and the transmitter's stability.

Troubleshooting:

If the transmitter is not providing expected readings, consult the troubleshooting guide provided in the manual or contact technical support for assistance.

Software Updates:

Keep the transmitter's firmware up-to-date to ensure the latest features and improvements are utilized.

Record Keeping:

Maintain records of maintenance activities, including dates, actions taken, and any parts replaced.

Packaging and Shipping

We take great care in packaging and shipping the rosemount 1151ap transmitter to ensure that it reaches our customers in perfect condition. Each transmitter is securely packaged to protect against damage during transit, and we offer a range of shipping options to meet your specific needs.

Contact Us

Shaaxi ZYY is a professional instrument company specializing in the sales of premium brands such as Emerson Rosemount, Yokogawa, Endress+Hauser, Azbil, Fisher, Honeywell, ABB, Siemens, and more. With over a decade of experience as a supplier, we offer a wide range of product models and are dedicated to providing professional solutions for our clients. For more product pricing information or to discuss your specific requirements, please contact us at lm@zyyinstrument.com. We look forward to serving you and becoming your trusted partner in the world of industrial instrumentation.

YOU MAY LIKE

Rosemount 3051tg Pressure Transmitter

Graphical backlit display, Bluetooth® connectivity

5-year warranty, range ratio 150:1

Support multiple communication protocols

Measuring range up to 1378.95bar

Various process wetted materials

Comprehensive diagnostic capabilities

SIL 2/3 certified according to IEC 61508 etc.

The wireless update rate is adjustable and the power module has a service life of 10 years.

Rosemount 2051TG Inline Pressure Transmitter

Graphical backlit display, Bluetooth® connectivity

5-year warranty, range ratio 150:1

Support multiple communication protocols

Measuring range up to 1378.95bar

Various process wetted materials

Comprehensive diagnostic capabilities

SIL 2/3 certified according to IEC 61508 etc.

The wireless update rate is adjustable and the power module has a service life of 10 years.

Rosemount 2051TA Pressure Transmitter

Range ratio up to 50:1 supports 4-20mA and 1-5V HART

Gauge pressure/absolute pressure up to 4000psig/a

Wetted material: 316L SST, alloy C276

Basic diagnostic function certification: NSF, NACE

Lightweight and compact design

Yokogawa Eja310a

View More

Yokogawa Ejx430a

Suitable for measuring liquid, gas or steam pressure.

Output 4~20mA DC current signal.

Fast response, remote setup and monitoring.

Diagnostic function to detect blockage of the pressure pipeline or abnormality of the heating system.

FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.

EJA440E

Used to measure the pressure of liquids, gases or vapors.

Outputs 4~20mA DC current signal.

Features quick response, remote setting and monitoring, and diagnostics.

Provides advanced diagnostic capabilities.

It can detect blockage of the pressure pipeline or abnormality of the heating system.

FF fieldbus type is available. Passed TÜV certification.

Meets SIL 2 safety requirements.

EJX530A Yokogawa

Output 4~20mA DC current signal.

Fast response, remote setup and monitoring.

Diagnostic functions: high/low pressure alarm output.

Multi-sensing technology detects anomalies. FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.