- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Benefits of using pressure transmitters in industrial processes

2024-07-09 16:14:29

Benefits of Using Pressure Transmitters in Industrial Processes

Introduction

In the unique scene of modern cycles, where accuracy and dependability are foremost, the job of Rosemount 2088G Inline Pressure Transmitter remains as a foundation of functional greatness. From the many-sided tasks of synthetic plants and treatment facilities to the complex work processes of assembling offices and power age units, keeping up with ideal pressure levels isn't simply a need yet a basic component for guaranteeing both proficiency and wellbeing. This exhaustive aide attempts to dig profoundly into the multi-layered advantages of integrating pressure transmitters inside modern settings, explaining how these refined instruments upgrade efficiency, protect work force, and smooth out activities to encourage supportable achievement.

At the core of modern tasks lies the basic to keep up with exact command over pressure factors. Pressure transmitters, furnished with state of the art detecting innovations and high level sign handling capacities, offer a solid means to accomplish this objective. By precisely estimating and sending pressure information continuously, these transmitters engage administrators with important bits of knowledge into the condition of basic cycles, working with informed direction and proactive mediations to deflect likely disturbances.

One of the essential benefits of pressure transmitters lies in their capacity to give ceaseless, precise pressure checking across a different scope of modern applications. Whether entrusted with observing liquid pressures inside pipelines, directing steam pressure in kettle frameworks, or controlling gas pressures in assembling processes, these flexible instruments succeed in conveying reliable and exact readings under fluctuating working circumstances. This steady dependability upgrades functional effectiveness as well as limits the gamble of expensive personal time and hardware disappointments, consequently enhancing resource usage and boosting efficiency.

Enhanced Accuracy and Precision

A foundation advantage in conveying pressure transmitters lies in their unmatched capacity to outfit exact and constant pressure readings. Not at all like ordinary mechanical measures, which are vulnerable to errors and slow floats in alignment, contemporary pressure transmitters stand apart for their outstanding unwavering quality and solidness. This dependability originates from their use of state of the art detecting innovations, including however not restricted to piezoelectric and strain check components, which support their ability to convey careful estimations. By outfitting the inborn accuracy of these detecting components, pressure transmitters engage administrators to maintain fastidious command over crucial cycle factors, consequently guaranteeing functional trustworthiness and effectiveness.

The prevalence of pressure transmitters in outfitting precise and continuous pressure information is highlighted by their refined plan and strong development. Outfitted with high-goal sensors and accuracy designed parts, these transmitters succeed in catching even the subtlest variances in pressure with unrivaled devotion. Besides, their high level sign handling calculations further improve estimation precision by sifting through clamor and obstruction, in this manner furnishing administrators with an unmistakable and unambiguous portrayal of the common pressure conditions.

Remote Monitoring and Control

In today's interconnected world, remote monitoring and control capabilities have become indispensable for industrial operations. Pressure transmitters, equipped with wireless communication protocols and digital interfaces, empower engineers and technicians to remotely monitor pressure levels and adjust settings from anywhere with an internet connection. This not only improves operational efficiency but also minimizes the need for on-site interventions, reducing downtime and maintenance costs.

Improved Safety and Risk Mitigation

Safety is paramount in industrial environments where high-pressure systems pose inherent risks to personnel and equipment. Rosemount 2088G Inline Pressure Transmitter play a crucial role in enhancing safety by providing early warnings of abnormal pressure conditions, such as leaks, overloads, or pressure spikes. By integrating these transmitters with automated safety systems and emergency shutdown mechanisms, operators can swiftly respond to potential hazards, mitigating risks and safeguarding assets.

Seamless Integration with Process Automation

In the contemporary scene of Industry 4.0, robotization remains at the bleeding edge of reforming modern cycles, introducing another period of extraordinary productivity gains and significant expense reserve funds. Inside this worldview, pressure transmitters expect a significant job as indispensable parts flawlessly coordinated into computerized control frameworks. Their consistent communicating with programmable rationale regulators (PLCs), circulated control frameworks (DCS), and administrative control and information procurement (SCADA) frameworks engages these transmitters to act as basic courses for transferring constant pressure information. This deluge of exact and prompt data into robotization stages lays the basis for the execution of complex control calculations, which assume an essential part in streamlining process boundaries and reducing changeability.

The coordination of pressure transmitters inside robotized control frameworks addresses a central empowering influence for the acknowledgment of upgraded functional efficiencies and financially savvy creation. By interacting with PLCs, these transmitters work with the execution of mechanized control procedures that answer progressively to fluctuating pressure conditions, in this way guaranteeing the support of ideal cycle boundaries. This unique responsiveness limits deviations from setpoint pressures as well as upgrades process strength, at last prompting further developed item quality and decreased asset utilization.

Cost Savings and Return on Investment (ROI)

While the initial investment in pressure transmitters may seem substantial, their long-term benefits far outweigh the costs. By ensuring precise pressure control, minimizing downtime, and preventing costly equipment failures, pressure transmitters contribute to significant cost savings over their operational lifespan. Moreover, the enhanced efficiency and productivity facilitated by these instruments translate into tangible returns on investment, making them indispensable assets for forward-thinking industrial enterprises.

Conclusion

In conclusion, the adoption of Rosemount 2088G Inline Pressure Transmitter offers a myriad of benefits for industrial processes, ranging from enhanced accuracy and remote monitoring to improved safety and cost savings. As industries continue to embrace digitalization and automation, pressure transmitters will play an increasingly pivotal role in optimizing operations and driving sustainable growth. To harness the full potential of these transformative instruments, it is essential for businesses to partner with reputable suppliers who offer high-quality products and reliable support services.

Contact us

Are you seeking a reliable partner for your pressure transmitter needs? Look no further! We are a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates to meet your requirements. Whether you need OEM support, fast delivery, or comprehensive testing services, we have you covered. Contact us today at lm@zyyinstrument.com to explore how we can collaborate and propel your business to new heights.

References

- "Pressure Transmitters: Applications and Benefits" - Emerson Electric Co.

- "Industrial Pressure Measurement Handbook" - WIKA Instrument, LP.

- "Principles of Industrial Instrumentation" - D. Patranabis.

- "Introduction to Process Control: Analysis, Mathematical Modeling, Control, and Optimization" - C. A. Desoer, E. S. Kuh.

- "Industrial Automation: Hands-On" - Frank Lamb.

YOU MAY LIKE

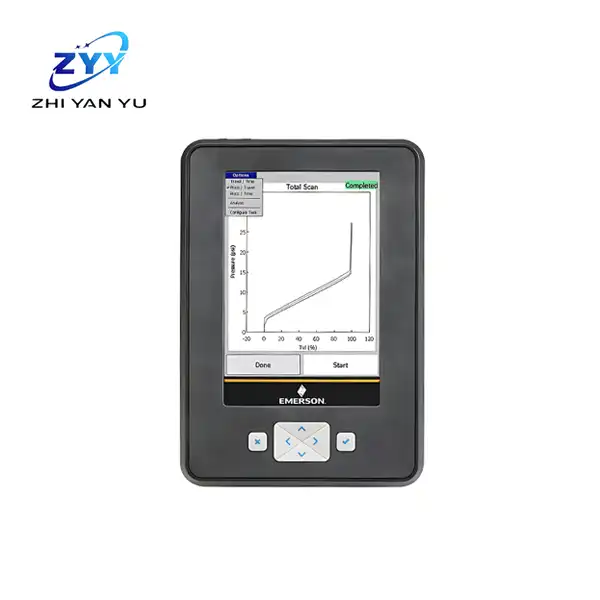

Emerson Ams Trex Device Communicator

Improve reliability and withstand harsh conditions assess safety

Microprocessor 800 MHZ ARM Cortex A8/NXP

Built-in flash memory 2 GB NAND and 32 GB extended flash memory RAM 512 MB DDR3 SDRAM

Display 5.7-inch (14.5 cm) color VGA resistive touch screen

Rosemount 2051 Coplanar Pressure Transmitter

Graphical backlit display, Bluetooth® connectivity

5-year warranty, range ratio 150:1

Support multiple communication protocols

Measuring range up to 1378.95bar

Various process wetted materials

Comprehensive diagnostic capabilities

SIL 2/3 certified according to IEC 61508 etc.

The wireless update rate is adjustable and the power module has a service life of 10 years.

Rosemount 2090P

Graphical backlit display, Bluetooth® connectivity

5-year warranty, range ratio 150:1

Support multiple communication protocols

Measuring range up to 1378.95bar

Various process wetted materials

Comprehensive diagnostic capabilities

SIL 2/3 certified according to IEC 61508 etc.

The wireless update rate is adjustable and the power module has a service life of 10 years.

Yokogawa Ejx430a

Suitable for measuring liquid, gas or steam pressure.

Output 4~20mA DC current signal.

Fast response, remote setup and monitoring.

Diagnostic function to detect blockage of the pressure pipeline or abnormality of the heating system.

FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.

Yokogawa EJA510E

Output 4~20mA DC current signal.

Fast response, remote setup and monitoring.

Diagnostic functions: high/low pressure alarm output.

Multi-sensing technology detects anomalies. FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.

Yokogawa EJA118E

Fast response, remote setting, diagnostics and optional pressure alarm output.

Multi-sensing technology detects abnormalities such as blockage in the pressure pipeline.

FF fieldbus type is available, and the standard configuration is TÜV certified and meets SIL 2 requirements.