- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Calibrate a Rosemount Temperature Transmitter?

2024-07-01 14:11:05

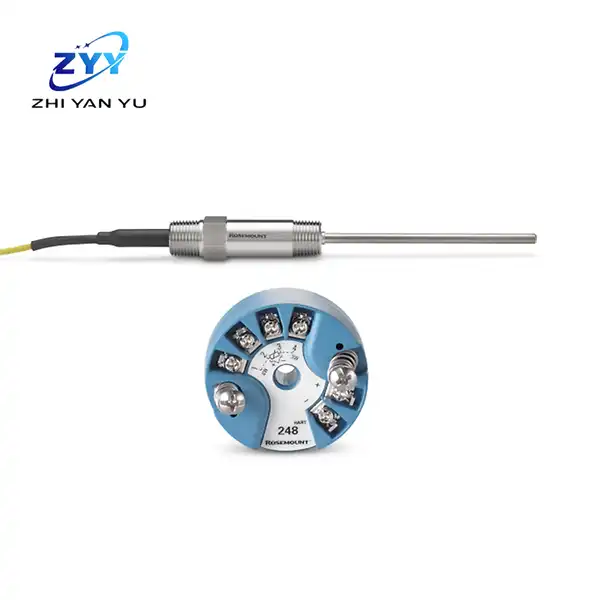

Temperature transmitters are crucial for maintaining accurate temperature measurements in various industrial applications. Calibration ensures that these transmitters provide precise readings. This blog will focus on how to calibrate the Rosemount 644 temperature transmitter, exploring its working principles, types, and applications. We will also address frequently asked questions related to the Rosemount 644 model.

How Does a Temperature Transmitter Work?

Temperature transmitters, such as the Rosemount 644, convert signals from temperature sensors into standardized output signals. These standardized signals (often 4-20 mA) facilitate easy data processing and integration into control systems.

Conversion Process

The conversion process involves several steps:

Signal Reception: The transmitter receives a low-level signal from the temperature sensor (RTD, thermocouple, etc.).

Signal Amplification: The weak sensor signal is amplified for better processing.

Linearization: The amplified signal is linearized to ensure a proportional relationship between the output signal and the temperature.

Standard Output: The linearized signal is converted into a 4-20 mA output, suitable for industrial applications.

The 4-20 mA signal is preferred because it is robust against signal loss and electrical noise, making it reliable for long-distance transmissions.

What Are the Calibration Steps for a Rosemount 644 Temperature Transmitter?

Calibration ensures the accuracy of the temperature transmitter. The process involves setting the transmitter to match known temperature points.

Step-by-Step Calibration

Zero Point Adjustment: Set the transmitter to output 4 mA at a known low-temperature point.

Span Adjustment: Set the transmitter to output 20 mA at a known high-temperature point.

Verification: Use a simulator to provide known resistance or voltage values and verify the transmitter's output against these values.

For digital calibration, software tools can be used, offering precision and ease of use compared to manual methods.

Detailed Calibration Process

Preparation:

Ensure that the transmitter and associated equipment are powered and functioning correctly.

Connect a reference thermometer or simulator to the transmitter.

Configure the simulation device to output the expected temperature range.

Zero Adjustment:

Set the simulator to the low end of the temperature range.

Adjust the transmitter to output 4 mA at this point.

Confirm that the transmitter reading matches the simulated temperature.

Span Adjustment:

Set the simulator to the high end of the temperature range.

Adjust the transmitter to output 20 mA at this point.

Verify the transmitter's reading against the simulated temperature.

Intermediate Checks:

Check multiple points between the zero and span settings to ensure linearity.

Record the readings to identify any deviations and adjust if necessary.

Documentation:

Document the calibration results for compliance and quality control.

Update the calibration records to reflect any adjustments made during the process.

How Does the Rosemount 644 Stand Out?

Advanced Diagnostics

The Rosemount 644 offers advanced diagnostics that help in identifying sensor degradation or wiring issues, facilitating proactive maintenance and reducing downtime. These diagnostics provide detailed information about sensor health, helping to predict failures before they occur.

Versatile Configuration

Supporting various communication protocols (HART, FOUNDATION Fieldbus, Profibus), the Rosemount 644 is highly adaptable to different control systems. Its configurable parameters allow for customization to specific application needs. This versatility makes it suitable for a wide range of industrial applications.

High Accuracy and Stability

With robust design and advanced sensor technology, the Rosemount 644 ensures high accuracy and stability, crucial for maintaining process control and product quality in harsh industrial environments. The transmitter is designed to withstand extreme conditions, ensuring reliable performance.

Digital Communication

The Rosemount 644 supports digital communication, enabling remote configuration and monitoring, which simplifies the management of multiple transmitters from a central location. This feature is particularly beneficial for large-scale operations, where manual adjustments can be time-consuming and impractical.

User-Friendly Interface

The user-friendly interface of the Rosemount 644 makes it easy to configure and calibrate. The intuitive software tools provided by Emerson allow for quick setup and adjustment, minimizing downtime and improving efficiency.

Why Is Calibration Essential for Temperature Transmitters?

Calibration is vital to ensure the output of the transmitter accurately represents the temperature being measured. It involves adjusting the transmitter to known temperature points to maintain accuracy and reliability over time.

Manual vs. Digital Calibration

Manual calibration involves physical adjustments, while digital calibration uses software, offering higher precision and easier adjustments. Regular calibration is crucial to identify measurement drifts and maintain optimal performance.

Frequency of Calibration

The frequency of calibration depends on several factors, including the operating environment, the criticality of the measurements, and the manufacturer's recommendations. In harsh environments, more frequent calibration may be necessary to ensure continued accuracy.

Impact on Process Control

Accurate temperature measurements are essential for process control in many industries. Incorrect readings can lead to process inefficiencies, product quality issues, and safety hazards. Regular calibration helps prevent these problems, ensuring smooth and efficient operations.

Compliance and Standards

Many industries are subject to strict regulatory standards that require regular calibration of measurement instruments. Ensuring compliance with these standards is crucial for legal and quality assurance purposes. Calibration records provide proof of compliance during audits and inspections.

Applications of Temperature Transmitters

Chemical and Petrochemical Industries

In chemical and petrochemical industries, temperature transmitters monitor temperatures in reactors and storage tanks, ensuring safety and efficiency. Accurate temperature control is vital for maintaining reaction rates and product quality.

Food and Beverage Industry

Temperature transmitters are essential in the food and beverage industry for maintaining quality and safety during cooking, cooling, and fermentation processes. Precise temperature control ensures that products meet health and safety standards.

HVAC Systems

Temperature transmitters help maintain optimal indoor climate conditions, improving energy efficiency and comfort. In HVAC systems, accurate temperature measurements are crucial for controlling heating, ventilation, and air conditioning equipment.

Power Generation

In power generation, temperature transmitters monitor the temperatures of steam and coolant, optimizing efficiency and preventing equipment damage. Accurate temperature control is essential for maintaining the performance and longevity of power generation equipment.

Pharmaceutical Industry

In the pharmaceutical industry, precise temperature control is crucial during drug and vaccine production, maintaining quality and regulatory compliance. Temperature transmitters ensure that production processes are conducted within the required temperature ranges.

Future Trends in Temperature Transmitter Technology

Future advancements include integration with IoT and Industry 4.0, enhancing data analytics, predictive maintenance, and process efficiency. Trends also include miniaturization, enhanced communication protocols, and improved accuracy and stability.

IoT and Industry 4.0

The integration of temperature transmitters with IoT and Industry 4.0 technologies enables real-time data collection and analysis. This integration allows for predictive maintenance, where potential issues are identified and addressed before they cause significant problems, improving operational efficiency and reducing downtime.

Miniaturization

Advancements in technology are leading to the miniaturization of temperature transmitters, making them more suitable for applications with limited space. Smaller transmitters can be used in compact installations without compromising on performance or accuracy.

Enhanced Communication Protocols

Improved communication protocols enhance the connectivity and interoperability of temperature transmitters with other devices and systems. This enhancement allows for seamless integration into complex industrial networks, facilitating better control and monitoring.

Improved Accuracy and Stability

Ongoing research and development efforts are focused on improving the accuracy and stability of temperature transmitters. Enhanced sensor technologies and advanced calibration techniques contribute to more reliable and precise temperature measurements.

Conclusion

Temperature transmitters like the Rosemount 644 are essential for accurate temperature monitoring and control in industrial processes. With advancements in technology, these devices are becoming more integrated, accurate, and versatile, ensuring enhanced process efficiency and safety. Regular calibration is crucial to maintain the accuracy and reliability of temperature transmitters, ensuring they provide precise readings over time.

For more information or to inquire about specific products, please contact us at lm@instrument.com.

References

Emerson. "Manual: Rosemount 644 Temperature Transmitter." Emerson.

Calibration Awareness. "5 Useful Setups on How to Calibrate a Temperature Transmitter."

Emerson. "Rosemount 3144P Temperature Transmitter | Emerson US."

ManualsLib. "EMERSON ROSEMOUNT 3144P REFERENCE MANUAL Pdf Download."

Emerson. "Manual: Rosemount 248 Temperature Transmitter."

Instrumart. "Rosemount 3144P Temperature Transmitter - Instrumart."

AutomationDirect Forum. "4-20 mA Signal Over Long Distances."

Calibration Awareness. "Temperature Calibration Basics."

Emerson. "Quick Start Guide: Rosemount 3144P HART Temperature Transmitter."

Emerson. "How to Calibrate Rosemount™ X-well™ Technology - Temperature."

For further inquiries and detailed product information, feel free to reach out to us at lm@instrument.com.

YOU MAY LIKE

ABB valve positioner V18345-1020121001

Rosemount ™ 214C thermal resistance temperature sensor

Rosemount 3051TA Absolute Pressure Transmitter

Yokogawa EJA438E diaphragm pressure transmitter

Yokogawa EJA440E high-performance pressure transmitter

E+H PMD75

Measurement: Operates by comparing pressures at these ports.

Use: Suitable for differential pressure applications.