- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Innovations and advancements in pressure transmitter technology

2024-06-28 15:52:22

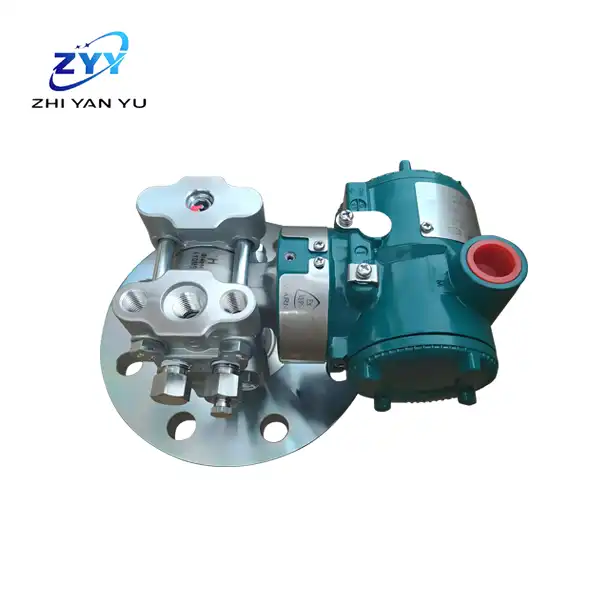

Rosemount 2088G Inline Pressure Transmitter technology has witnessed remarkable advancements in recent years, revolutionizing various industries' processes and operations. As a professional in the field, I have delved into the latest innovations shaping this critical component of modern industrial systems. In this comprehensive article, I will explore the significant developments in pressure transmitter technology, providing insights into how these innovations are enhancing efficiency, accuracy, and reliability across diverse applications.

1. Introduction to Pressure Transmitters

Pressure transmitters are essential components in industrial processes, providing critical oversight and regulation of pressure levels to enhance operational efficiency and safety. By transforming pressure measurements into electrical signals, these devices enable real-time monitoring and data-informed decision-making. The evolution of sensor technology, signal processing, and communication protocols has significantly elevated the precision and functionality of pressure transmitters, underscoring their indispensable role in modern industrial operations.

2. Evolution of Pressure Sensing Technologies

The evolution of Rosemount 2088G Inline Pressure Transmitter technologies has been a pivotal catalyst driving the remarkable advancements in pressure transmitter technology. The traditional reliance on mechanical and pneumatic pressure sensors has undergone a profound transformation with the emergence of state-of-the-art electronic and MEMS (Microelectromechanical Systems) sensors. This paradigm shift has revolutionized the landscape of pressure measurement. It usheres in a new era characterized by heightened precision, unparalleled stability, and exceptional responsiveness.

The transition to electronic and MEMS sensors represents a quantum leap in the pursuit of superior performance and reliability. By harnessing cutting-edge materials and innovative fabrication techniques, these advanced sensors have redefined the benchmarks for accuracy and adaptability in pressure measurement applications. The result is a suite of sensor technologies capable of delivering precise pressure readings across an extensive spectrum of operating conditions. That empowers industries with invaluable insights and control over their processes.

Moreover, the integration of smart functionalities and advanced signal processing techniques has further amplified the capabilities of modern pressure transmitters.These innovations have not only elevated the accuracy and predictive capabilities of pressure sensing technologies but have also facilitated seamless integration with industrial automation systems, enabling real-time monitoring and data-driven decision-making.

3. Integration of Wireless Communication

The integration of wireless communication capabilities has been a game-changer in Rosemount 2088G Inline Pressure Transmitter design, enabling seamless connectivity and remote monitoring in industrial environments. Modern pressure transmitters are equipped with wireless communication protocols such as Bluetooth, Wi-Fi, and LoRaWAN, allowing for easy integration with IoT (Internet of Things) platforms and industrial automation systems. This wireless connectivity empowers operators to monitor pressure levels in real-time, optimize processes, and preemptively address potential issues.

4. Advancements in Calibration and Diagnostics

The evolution of calibration and diagnostics in Rosemount 2088G Inline Pressure Transmitter technology has emerged as a pivotal enabler of precise and dependable performance in industrial settings. The intricate interplay between calibration accuracy and diagnostic capabilities has undergone a paradigm shift, driven by a wave of innovative techniques and algorithms designed to elevate the reliability and predictive insights embedded within pressure transmitters.

In recent years, a notable surge in digital calibration methodologies and self-calibration algorithms has ushered in a new era of simplicity and precision in the calibration process. These advancements have effectively streamlined the intricacies of calibration, optimizing the accuracy and repeatability of pressure measurements while minimizing the need for manual intervention. This transformative shift has significantly enhanced the operational efficiency of pressure transmitters, setting new benchmarks for precision and reliability across diverse industrial applications.

Simultaneously, the integration of advanced diagnostic features has fortified the resilience of pressure transmitters against potential faults and operational irregularities. Robust fault detection mechanisms and predictive maintenance algorithms have empowered proactive identification and resolution of potential issues, thereby mitigating downtime and fortifying operational resilience. These sophisticated diagnostic capabilities not only optimize the performance of pressure transmitters but also engender a proactive approach to maintenance, fostering a culture of efficiency and reliability in industrial operations.

Furthermore, the convergence of advanced analytics and machine learning techniques has propelled the diagnostic capabilities of pressure transmitters to unprecedented heights. By harnessing the power of real-time data analysis and predictive modeling, modern pressure transmitters can anticipate and address potential issues with unparalleled accuracy and foresight, underpinning a new era of predictive maintenance and operational excellence.

As the trajectory of advancements in calibration and diagnostics continues to unfold, the industry is poised to witness a transformative shift in the reliability, accuracy, and predictive insights offered by pressure transmitter technology, setting new standards for performance and resilience in industrial settings.

5. Application-Specific Innovations

In response to evolving industry requirements, Rosemount 2088G Inline Pressure Transmitter manufacturers have developed application-specific innovations tailored to various industrial sectors. Whether it's the oil and gas industry, pharmaceutical manufacturing, or automotive production, specialized pressure transmitters with custom features and capabilities are addressing specific challenges and improving overall system performance. From high-temperature resistance to corrosive media compatibility, these innovations ensure reliable operation in demanding environments.

In conclusion, the advancements in pressure transmitter technology are driving unprecedented levels of efficiency, accuracy, and reliability across industries worldwide. From the integration of wireless communication and sophisticated sensor technologies to application-specific innovations, the landscape of pressure measurement is continually evolving to meet the demands of modern industrial processes. As a leading manufacturer and supplier in this field, we are committed to delivering cutting-edge solutions that empower our customers to achieve their operational goals efficiently and effectively.

Contact Us

For professional-grade pressure transmitters and comprehensive support, contact us at lm@zyyinstrument.com. As a GMP-certified manufacturing supplier with a large inventory and complete certificates, we offer OEM support, fast delivery, and tight packaging. Partner with us to access top-quality pressure transmitter solutions tailored to your specific requirements.

References

- "Pressure Transmitter Market - Growth, Trends, COVID-19 Impact, and Forecasts (2021 - 2026)" - Mordor Intelligence.

- "Industrial Pressure Transmitter Market Size, Share & Trends Analysis Report By Type, By Application, By Region, And Segment Forecasts, 2020 - 2027" - Grand View Research.

- "Wireless Pressure Transmitter Market Forecast, Trend Analysis & Competition Tracking - Global Market Insights 2021 to 2031" - Future Market Insights.

- "Advances in Pressure Sensor Technology" - Sensors Online.

- "MEMS Pressure Sensor Technology for Industrial Applications" - Analog Devices.

YOU MAY LIKE

Azbil Smart Valve Positioner

Compatibility: Suitable for both linear and quarter-turn actuators.

Operation: Actuator movement rotates the feedback shaft.

Sensing: The position sensor detects the valve position and converts it to an electrical signal.

Control: An electronic module calculates deviation and controls the drive module to adjust valve positioning precisely.

Rosemount 2090P

Graphical backlit display, Bluetooth® connectivity

5-year warranty, range ratio 150:1

Support multiple communication protocols

Measuring range up to 1378.95bar

Various process wetted materials

Comprehensive diagnostic capabilities

SIL 2/3 certified according to IEC 61508 etc.

The wireless update rate is adjustable and the power module has a service life of 10 years.

EJX120A Yokogawa

Suitable for measuring flow, level, density and pressure of liquid, gas or steam.

Output 4~20mA DC current signal.

Can measure static pressure.

Built-in display meter display or remote monitoring.

Fast response, remote setting, diagnostics and optional high/low pressure alarm output.

The diagnostic function can detect blockages in the pressure line or abnormalities in the heating system.

FF fieldbus type is available.

Except for the FF fieldbus type, it has passed TÜV certification and meets SIL 2 safety requirements.

Yokogawa EJA210E

Measure static pressure with built-in display or remote monitoring.

Fast response, remote setting, diagnostics and optional pressure alarm output.

Multi-sensing technology detects abnormalities such as blockage in the pressure pipeline.

FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.

Rosemount 8732E

Pipe Sizes: Ranges from 15-900mm (½-36in).

Lining Materials: PTFE, ETFE, PFA, polyurethane, etc.

Electrode Materials: 316L stainless steel, nickel alloys, etc.

Flange Ratings: ASME B16.5 150-2500, DIN PN 10-40, AS 2129 Table D, and AWWA C207 Table 3 D.

Submersion Protection: IP68 (recommended with sealed cable glands).

Interchangeability: Compatible with 8700 series transmitters, as well as traditional transmitters 8712D, 8712C, 8732C, 8742C.

Design: Unobstructed design to minimize maintenance and repair needs.

Rosemount 8721

Pipe Sizes: Ranges from 15-900mm (½-36in).

Lining Materials: PTFE, ETFE, PFA, polyurethane, etc.

Electrode Materials: 316L stainless steel, nickel alloys, etc.

Flange Ratings: ASME B16.5 150-2500, DIN PN 10-40, AS 2129 Table D, and AWWA C207 Table 3 D.

Submersion Protection: IP68 (recommended with sealed cable glands).

Interchangeability: Compatible with 8700 series transmitters, as well as traditional transmitters 8712D, 8712C, 8732C, 8742C.

Design: Unobstructed design to minimize maintenance and repair needs.