- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Temperature transmitter redundancy and failover strategies

2024-07-05 16:56:07

Temperature Transmitter Redundancy and Failover Strategies

Understanding the Importance of Temperature Transmitter Redundancy

In industrial settings where temperature monitoring is critical, ensuring continuous and reliable operation is paramount. Temperature transmitters play a vital role in this process, converting temperature readings into electrical signals for monitoring and control systems. Redundancy ensures continuity of operations and mitigates the risk of system failure or downtime due to transmitter malfunction or failure.

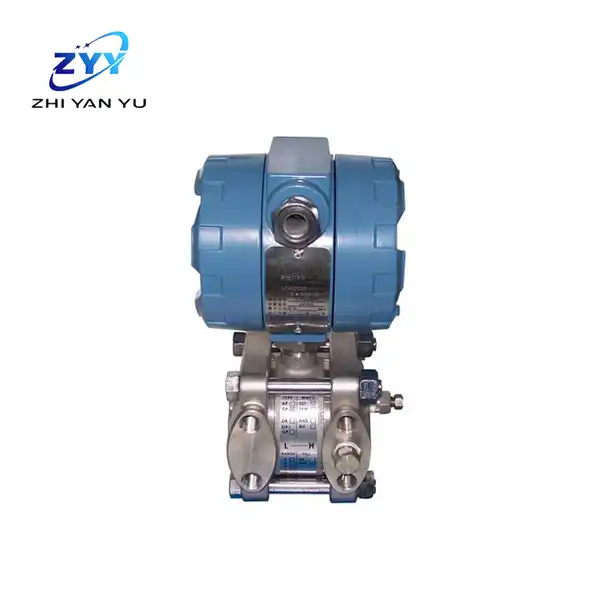

Having Siemens Pressure Transmitter means that if one transmitter fails or malfunctions, another one immediately takes over to continue monitoring and controlling temperature parameters. This overt repetitiveness gives an extra layer of dependability and guarantees that temperature-delicate cycles can continue without interference, limiting the gamble of item misfortune or compromised quality. Besides, overt repetitiveness improves wellbeing by giving a reinforcement framework to forestall potential perils related with temperature deviations, for example, hardware harm or item defilement. Be that as it may, even the most solid transmitters can encounter disappointments, prompting expected free time and dangers. To alleviate these dangers, it is vital for execute overt repetitiveness and failover methodologies.

Exploring Redundancy Options for Temperature Transmitters

One approach to enhancing reliability is through redundancy, which involves the use of backup components or systems to take over in case of failure. Exploring redundancy options for siemens pressure transmitter 7mf4433 involves implementing backup systems to ensure continuous temperature monitoring and control in critical processes. One common approach is to install dual temperature transmitters, where two separate transmitters are installed to monitor the same temperature parameter simultaneously.

These transmitters can operate independently, providing redundancy in case one fails or malfunctions. Additionally, they can be connected to a voting logic system that compares their readings and activates an alarm or switches to the backup transmitter if discrepancies are detected.

Another choice is hot reserve overt repetitiveness, where one transmitter fills in as the essential unit while one more remaining parts on backup, prepared to dominate in the event that the essential transmitter falls flat. This arrangement requires quick changing components to guarantee consistent progress without disturbing tasks. With regards to temperature transmitters, there are a few overt repetitiveness choices accessible, each with its benefits and contemplations. These incorporate equipment overt repetitiveness, programming overt repetitiveness, and correspondence overt repetitiveness, each offering remarkable advantages in guaranteeing continuous temperature checking and control.

Hardware Redundancy: Doubling Up for Reliability

Hardware redundancy involves the use of duplicate components or systems to provide backup in case of failure. In the case of temperature transmitters, this may include redundant sensors, power supplies, or even entire transmitter units. Redundancy can be implemented at various levels, including power supplies, storage devices, network interfaces, and entire servers or data centers.

Overt repetitiveness techniques like Strike (Excess Exhibit of Autonomous Circles) away frameworks, hot-swappable parts, and failover grouping in servers are normal models. While equipment overt repetitiveness increments forthright expenses and intricacy, it gives priceless advantages in strategic conditions where continuous activity is principal. This overt repetitiveness guarantees coherence of administration, diminishes the gamble of information misfortune, and upgrades generally speaking framework flexibility. By having copy equipment set up, any disappointment in one part can be flawlessly moderated by changing to the excess unit, limiting free time and guaranteeing consistent temperature observing and control.

Software Redundancy:

Guaranteeing Flexibility through Programming overt repetitiveness centers around copying basic programming parts or executing failover instruments inside the actual product. For Siemens Pressure Transmitter, this might include excess programming rationale or issue lenient calculations that can distinguish and make up for blunders or disappointments. By consolidating programming overt repetitiveness measures, temperature observing frameworks can keep up with unwavering quality even despite programming errors or glitches. This overt repetitiveness guarantees proceeded with activity in case of programming disappointments or blunders. There are different ways to deal with carrying out programming overt repetitiveness, including:

1. N-Adaptation Programming: Fostering various forms of programming freely, then, at that point, running them simultaneously and contrasting their results with recognize mistakes.

2.Checkpointing and Rollback: Periodically saving the system's state (checkpointing) and rolling back to a previous checkpoint if errors occur, ensuring continuous operation.

3.Hot Standby: Running redundant copies of software simultaneously, with one actively processing data while the other remains on standby. If the active copy fails, the standby copy takes over seamlessly.

4.Failover Clustering: Distributing software across multiple nodes in a cluster, with automatic failover mechanisms to redirect traffic to healthy nodes if one fails.

Communication Redundancy:

Safeguarding Data Transmission In addition to hardware and software redundancy, siemens pressure transmitter 7mf4433 is crucial for ensuring robustness in temperature monitoring systems. This involves using multiple communication channels or protocols to transmit temperature data to monitoring and control systems. By having redundant communication pathways in place, such as wired and wireless connections or dual communication protocols, the risk of data loss or communication failures can be significantly reduced. Several techniques are employed to achieve communication redundancy:

1.Multiple Paths: Establishing multiple physical or logical communication paths between network nodes to provide alternative routes in case of failures or congestion.

2.Redundant Hardware: Deploying redundant networking equipment such as routers, switches, and communication links to maintain connectivity even if primary components fail.

3.Protocol Redundancy: Implementing multiple communication protocols to facilitate communication diversification and ensure interoperability in case of protocol-specific issues.

4.Load Balancing: Distributing network traffic across multiple communication paths or links to prevent overloading and improve overall network performance and resilience.

As industries increasingly rely on temperature monitoring for process control and safety, the importance of redundancy and failover strategies cannot be overstated. By implementing hardware redundancy, software redundancy, and communication redundancy, organizations can enhance the reliability and resilience of their temperature monitoring systems, minimizing downtime and ensuring continuous operation.

The full sulfur hexafluoride circuit breaker is a critical component in many industrial applications, providing reliable protection against electrical faults. However, like any equipment, circuit breakers can experience failures, highlighting the importance of redundancy and failover strategies in ensuring uninterrupted power distribution.

In conclusion, Siemens Pressure Transmitter and failover strategies are essential for maintaining the reliability and resilience of temperature monitoring systems in industrial settings. By understanding the different redundancy options available and implementing robust failover mechanisms, organizations can minimize downtime, enhance safety, and ensure uninterrupted operation.

Contact us:

For professional manufacturing suppliers with a GMP factory, large inventory, complete certificates, and support OEM, contact us at lm@zyyinstrument.com for fast delivery, tight packaging, and support testing. Let's collaborate to meet your industrial needs efficiently and reliably.

References:

- "Temperature Transmitters: Redundancy Strategies and Failover Mechanisms" - Industrial Automation Magazine

- "Reliability Engineering for Industrial Control Systems" - IEEE Transactions on Industrial Electronics

- "Communication Redundancy in Industrial Networks" - International Journal of Distributed Sensor Networks

YOU MAY LIKE

Honeywell St800 Pressure Transmitter

The output signal is usually 4-20mA.

Signal is linearly related to pressure.

The control panel adjusts the sensitive components.

Provides output signal calibration options.

Pressure testing ensures resistance to extreme pressures.

Azbil Smart Valve Positioner

Compatibility: Suitable for both linear and quarter-turn actuators.

Operation: Actuator movement rotates the feedback shaft.

Sensing: The position sensor detects the valve position and converts it to an electrical signal.

Control: An electronic module calculates deviation and controls the drive module to adjust valve positioning precisely.

Yokogawa Temperature Transmitter Yta610

Converted to 4-20 mA DC signal or fieldbus signal output.

It is divided into HART communication type and FOUNDATIONTM fieldbus communication type.

The HART communication type complies with the SIL2 safety level.

Rosemount 2090F

Graphical backlit display, Bluetooth® connectivity

5-year warranty, range ratio 150:1

Support multiple communication protocols

Measuring range up to 1378.95bar

Various process wetted materials

Comprehensive diagnostic capabilities

SIL 2/3 certified according to IEC 61508 etc.

The wireless update rate is adjustable and the power module has a service life of 10 years.

Rosemount 1151ap Absolute Pressure Transmitter

Range ratio up to 50:1 supports 4-20mA and 1-5V HART

Gauge pressure/absolute pressure up to 4000psig/a

Wetted material: 316L SST, alloy C276

Basic diagnostic function certification: NSF, NACE

Lightweight and compact design

EJX530A Yokogawa

Output 4~20mA DC current signal.

Fast response, remote setup and monitoring.

Diagnostic functions: high/low pressure alarm output.

Multi-sensing technology detects anomalies. FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.