- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Training and certification programs for valve positioner technicians and engineers

2024-07-26 20:21:54

Title: Training and Certification Programs for Valve Positioner Technicians and Engineers

Subtitles:

1. Figuring out Valve Positioners: Essentials and Significance

2. Fundamental Abilities for Valve Positioner Professionals and Designers

3. Investigating Preparing Projects for Valve Positioner Experts

4. Confirmation and License: Guaranteeing Quality and Ability

5. Benefits of Specific Preparation in Valve Positioner Innovation

ABB Valve Positioner assume a significant part in the effective and precise working of different modern cycles, from assembling to energy creation. As a valve positioner professional or designer, having the fundamental abilities and skill is vital for guaranteeing the ideal presentation and unwavering quality of these frameworks. In this thorough aide, we will dig into the universe of valve positioners, investigate the preparation and accreditation programs accessible for experts in this field, and feature the significance of specific information in valve positioner innovation.

Understanding Valve Positioners: Fundamentals and Importance

Before delving into the intricacies of training and certification programs, it's essential to grasp the fundamentals of valve positioners and their significance in industrial applications. Valve positioners are devices used to control the position of a valve actuator based on external signals, ensuring precise regulation of flow rates, pressures, and other process variables.In enterprises like oil and gas, petrochemicals, and power age, where unwavering quality and productivity are principal, valve positioners assume a basic part in keeping up with functional respectability and streamlining execution.

Valve positioners are critical components in industrial automation systems, designed to accurately position control valves based on input signals from process controllers or instruments. They ensure precise control over fluid flow, pressure, temperature, and other process variables, thus playing a fundamental role in optimizing industrial processes.The importance of valve positioners lies in their ability to enhance control precision and system reliability. By precisely positioning control valves, they enable tighter control over process parameters, leading to improved product quality, reduced waste, and increased efficiency.This accuracy is particularly urgent in ventures like oil and gas, substance handling, power age, and water treatment, where even little deviations from setpoints can have huge ramifications.

Essential Skills for Valve Positioner Technicians and Engineers

Becoming proficient in ABB Valve Positioner technology requires a diverse skill set encompassing mechanical, electrical, and instrumentation expertise. Valve positioner technicians and engineers need to have a deep understanding of pneumatic and electronic control systems, as well as knowledge of various valve types and their operating principles. Also, investigating abilities, experience with industry guidelines and guidelines, and the capacity to decipher specialized drawings and schematics are fundamental for really diagnosing and settling issues in valve control frameworks. Here are a few fundamental abilities for experts in this field:

1.Technical Capability: A profound comprehension of valve frameworks, including their parts, activity standards, and control instruments, is urgent. This includes knowledge of pneumatic, hydraulic, and electric actuators, as well as valve types and configurations.

2.Troubleshooting Skills: The ability to diagnose and rectify issues with valve positioners is essential. Technicians should be adept at identifying mechanical problems, electrical faults, and control loop issues to ensure optimal valve performance.

3.Calibration and Maintenance: Proficiency in calibrating and maintaining valve positioners is necessary to ensure accurate and reliable operation. This involves understanding calibration procedures, performing routine maintenance tasks, and recognizing when repairs or replacements are needed.

4. Instrumentation Information: Experience with instrumentation and control frameworks is fundamental for valve professionals and designers. This incorporates figuring out process factors, instrumentation gadgets, and control systems utilized in modern conditions.

5. Relational abilities: Compelling correspondence is essential for planning with colleagues, passing specialized data on to partners, and recording support exercises. Clear and succinct correspondence forestalls errors and guarantees that assignments are finished effectively.

Exploring Training Programs for Valve Positioner Professionals

To procure the vital abilities and information expected for working with ABB Valve Positioner, hopeful experts and designers can profit from specific preparation programs presented by trustworthy foundations and preparing suppliers. Search for programs that give involved experience different kinds of valve positioners and actuators, as well as pragmatic preparation in instrumentation and control frameworks. Additionally, courses that delve into industry-specific applications and best practices for maintenance and optimization can be highly beneficial. Consider seeking out training programs offered by reputable technical institutes, professional organizations, or valve manufacturers to ensure high-quality education and relevant certifications in the field.These programs typically cover a wide range of topics, including valve fundamentals, control theory, calibration techniques, maintenance procedures, and safety protocols. Hands-on practical training, supplemented by theoretical coursework and real-world case studies, equips participants with the practical skills and confidence needed to excel in their roles.

Certification and Accreditation: Ensuring Quality and Expertise

In addition to completing training programs, obtaining certification in valve positioner technology demonstrates a commitment to excellence and proficiency in the field. Certification programs, offered by industry organizations and professional associations, assess candidates' knowledge, skills, and competency through rigorous examinations and practical assessments. Achieving certification not only enhances professional credibility but also opens up new career opportunities and signifies a dedication to continuous learning and professional development.

Advantages of Specialized Training in Valve Positioner Technology

Investing in specialized training and certification in ABB Valve Positioner technology offers numerous benefits for both individuals and organizations. For professionals, it provides a competitive edge in the job market, increases earning potential, and expands career prospects in industries that rely on advanced process control systems. Managers, then again, benefit from having a gifted and proficient labor force equipped for improving valve execution, lessening margin time, and upgrading functional productivity. By prioritizing training and certification in valve positioner technology, organizations can ensure the reliability and longevity of their critical infrastructure while maintaining a competitive advantage in the marketplace.

Contact us

For professional manufacturing solutions, contact us at lm@zyyinstrument.com. We are a GMP factory with a large inventory, complete certificates, and support OEM. With fast delivery, tight packaging, and comprehensive testing support, we welcome global buyers to cooperate with us.

References:

- American Society of Mechanical Engineers (ASME) - www.asme.org

- International Society of Automation (ISA) - www.isa.org

- Valve Manufacturers Association (VMA) - www.vma.org

- Occupational Safety and Health Administration (OSHA) - www.osha.gov

- National Institute for Certification in Engineering Technologies (NICET) - www.nicet.org

YOU MAY LIKE

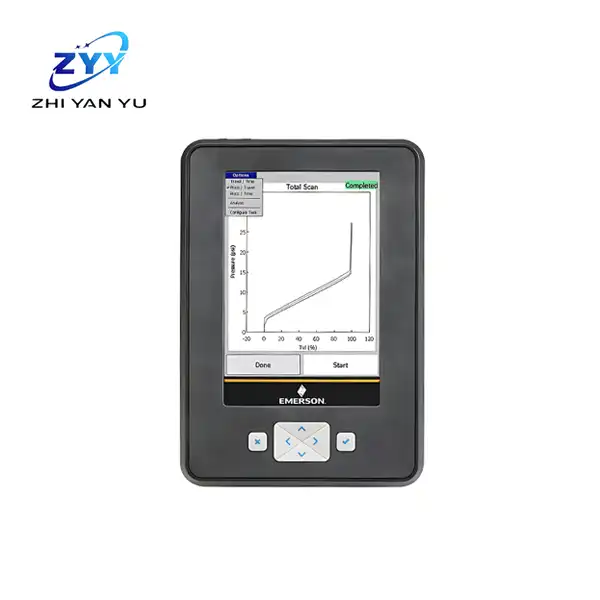

Emerson Ams Trex Device Communicator

Improve reliability and withstand harsh conditions assess safety

Microprocessor 800 MHZ ARM Cortex A8/NXP

Built-in flash memory 2 GB NAND and 32 GB extended flash memory RAM 512 MB DDR3 SDRAM

Display 5.7-inch (14.5 cm) color VGA resistive touch screen

Yokogawa Eja310e

View More

E&H Pmd76 Differential Pressure Transmitter

View MoreRosemount Micro Motion Coriolis Mass Flow Meter

Self-Verification: Features Smart Meter Verification™ for complete, traceable calibration checks.

Calibration Facility: Supported by a world-leading ISO/IEC 17025 calibration facility for high performance.

Smart Sensor Design: Reduces the need for onsite zero calibration.

Yokogawa Vortex Flowmeter

High reliability and robust design improve factory efficiency

Reduce operating costs and facilitate parameter setting

Clear display, analog/pulse dual output

Alarm output, status output (flow switch)

Stainless steel detector with no moving parts

Signal cable length max. 30 m

Explosion-proof structure: NEPSI

Axf Magnetic Flowmeter

Unobstructed flowing parts

Large nominal diameter range

Novel excitation method

Converter and sensor can be separated

High microprocessor performance

Bidirectional measuring system

Self-test and self-diagnostic functions