- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is a Differential Pressure Transmitter?

2024-07-11 14:15:38

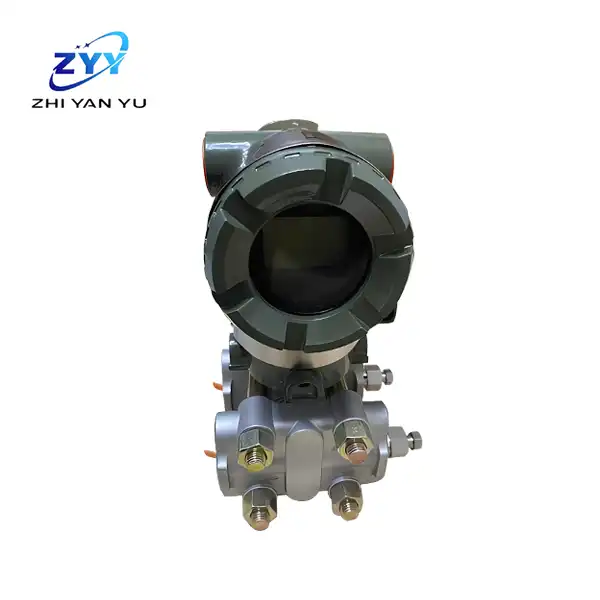

Differential pressure transmitters are critical components in various industrial processes, providing precise measurements of pressure differences between two points. These measurements are vital for applications such as flow measurement, filter monitoring, and liquid level measurement. In this blog, we'll delve into what differential pressure transmitters are, with a special focus on the Yokogawa EJA110E, a renowned model in the industry.

What Are the Key Features of the Yokogawa EJA110E Differential Pressure Transmitter?

The Yokogawa EJA110E is a popular differential pressure transmitter known for its reliability and accuracy. Understanding its key features can help determine its suitability for various applications. The EJA110E boasts:

High Accuracy: With an accuracy of ±0.04% of the span, the EJA110E ensures precise measurements crucial for critical processes.

Robust Design: Built to withstand harsh environments, it features a robust construction that ensures durability and longevity.

Advanced Diagnostics: The EJA110E comes with advanced self-diagnostic features that enhance maintenance and reliability.

Wide Range of Applications: It is suitable for a broad range of applications, from simple flow measurement to complex process monitoring.

These features make the Yokogawa EJA110E a versatile and dependable choice for various industrial settings.

How Does a Differential Pressure Transmitter Work?

Understanding how a differential pressure transmitter works is essential for selecting the right one for your needs. The basic working principle involves measuring the pressure difference between two points and converting this differential pressure into an electrical signal that can be read and interpreted by control systems.

Pressure Sensing Element: The transmitter contains a pressure sensing element, typically a diaphragm, that deforms proportionally to the pressure difference.

Transduction Mechanism: This deformation is converted into an electrical signal by a transduction mechanism, such as a capacitive or piezoelectric sensor.

Signal Processing: The electrical signal is then processed and calibrated to provide a precise measurement of the pressure difference.

Yokogawa’s EJA110E uses advanced sensor technology to ensure that the signal processing is highly accurate and reliable.

What Are the Applications of Yokogawa EJA110E in Different Industries?

The versatility of the Yokogawa EJA110E makes it suitable for a wide range of applications across various industries. Here are some common applications:

Flow Measurement: In conjunction with a primary element like an orifice plate or venturi tube, the EJA110E can accurately measure the flow rate of gases, liquids, and steam.

Liquid Level Measurement: The EJA110E can measure the level of liquids in tanks and vessels by calculating the pressure difference between the top and bottom of the container.

Filter Monitoring: It helps in monitoring filter conditions by measuring the pressure drop across the filter, indicating when maintenance is required.

Process Control: It plays a crucial role in process control systems by providing precise pressure measurements needed for maintaining optimal operating conditions.

These applications demonstrate the flexibility and importance of the Yokogawa EJA110E in maintaining efficient and reliable industrial operations.

How Do You Install and Calibrate the Yokogawa EJA110E?

Proper installation and calibration are vital to ensure the accurate performance of the Yokogawa EJA110E. Here’s a step-by-step guide:

Installation:

Mounting: Securely mount the transmitter in an appropriate location, ensuring it is free from excessive vibrations and environmental factors that could affect its performance.

Connection: Connect the pressure ports to the points of interest in the process system using appropriate tubing and fittings.

Electrical Wiring: Connect the transmitter to the control system using the recommended wiring practices to ensure reliable communication and power supply.

Calibration:

Zero Adjustment: Before starting the calibration, ensure that the transmitter is at zero pressure differential (both pressure ports exposed to the same pressure) and adjust the zero setting if necessary.

Span Calibration: Apply known pressure differentials across the transmitter and adjust the span setting to match the corresponding electrical output signal.

Verification: Verify the calibration by applying pressure differentials within the operating range and checking the output signal for accuracy.

Regular calibration ensures that the Yokogawa EJA110E maintains its accuracy and reliability over time.

What Are the Maintenance Best Practices for Yokogawa EJA110E?

Maintaining the Yokogawa EJA110E involves routine checks and preventive measures to ensure its long-term performance and reliability. Here are some best practices:

Regular Inspections: Conduct regular visual inspections to check for signs of wear, damage, or corrosion on the transmitter and its connections.

Cleaning: Keep the pressure ports and diaphragm clean from debris and buildup that could affect the accuracy of measurements.

Calibration Checks: Perform periodic calibration checks to ensure that the transmitter remains accurate and adjust as necessary.

Firmware Updates: Keep the transmitter’s firmware up to date to benefit from the latest improvements and features provided by Yokogawa.

Adhering to these maintenance practices can significantly extend the lifespan of the Yokogawa EJA110E and ensure continuous accurate performance.

Conclusion

Differential pressure transmitters like the Yokogawa EJA110E are indispensable tools in various industrial processes, offering precise and reliable pressure measurements. By understanding their features, working principles, applications, installation, calibration, and maintenance, you can make an informed decision and ensure optimal performance in your operations.

References

Yokogawa Corporation of America. "Differential Pressure Transmitters."

Yokogawa Electric Corporation. "EJA110E Differential Pressure Transmitter User's Manual."

Yokogawa America. "Differential Pressure Transmitter Overview."

Control Global. "Selecting the Right Differential Pressure Transmitter."

Yokogawa Electric Corporation. "Calibration and Maintenance of Differential Pressure Transmitters."

DirectIndustry. "Differential Pressure Transmitter Applications."

Yokogawa Electric Corporation. "EJA110E Product Specifications."

Yokogawa Electric Corporation. "Advanced Diagnostic Features of the EJA110E."

Yokogawa Electric Corporation. "EJA Series Pressure Transmitters."

Yokogawa Electric Corporation. "Best Practices for Installing Differential Pressure Transmitters."

For more information, feel free to contact us at lm@zyyinstrument.com for more product details.

YOU MAY LIKE

Rosemount ™ 3051TG direct connection pressure transmitter

Yokogawa EJX440A high-performance pressure transmitter

Yokogawa Temperature Transmitter YTA110

Converted to 4-20 mA DC signal or fieldbus signal output.

It is divided into HART communication type and FOUNDATIONTM fieldbus communication type.

The HART communication type complies with SIL2 safety level.

Yokogawa EJX210A flange-mounted differential pressure transmitter

E+H PMD75

Measurement: Operates by comparing pressures at these ports.

Use: Suitable for differential pressure applications.